Certain plastic materials come with phenomenal UV resistant capabilities. These plastics are essential for outdoor applications. Let’s begin and see the list of best UV resistant plastic materials.

What are the 7 Best UV Resistant Plastics

When choosing the right plastic for your applications, many things must be considered. Let’s talk about selecting UV-resistant plastics and why it is so important.

UV resistant material is necessary for various outdoor applications such as marine dock fenders, mass transportation interiors, architectural glazing, etc.

UV radiation can be very harmful to a plastic product and cause degradation. Several UV-resistant plastic materials are available that make our job relatively easy.

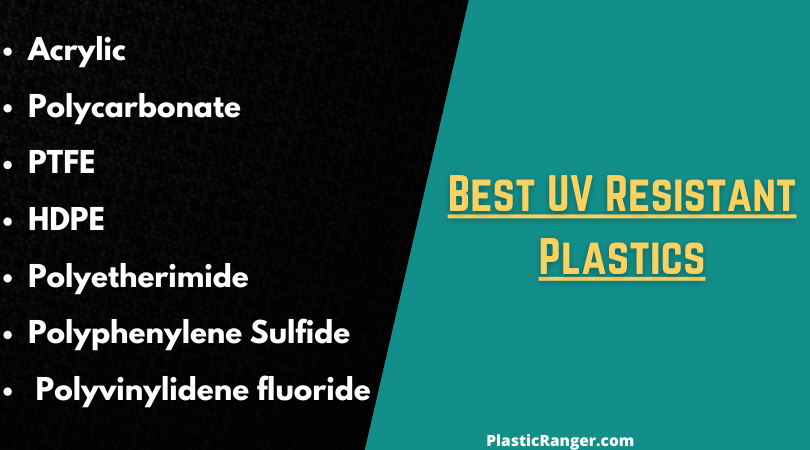

Without further ado, let’s start our list of the best UV resistant plastic materials:

Top UV Resistant Plastics

- Acrylic

- Polycarbonate

- PTFE

- HDPE

- Polyetherimide

- Polyphenylene Sulfide

- Polyvinylidene fluoride

Acrylic

Acrylic is the most notable material used in outdoor applications for UV resistance. Also called PMMA (Polymethyl methacrylate), it is a transparent thermoplastic material better known by its chemical name “plexiglass.”

In addition to being UV resistant, acrylic possesses high rigidity, excellent strength, and optical clarity. The UV-resistant clear material has many similarities with polycarbonate and is also used as a replacement for glass.

The most popular applications for acrylic are light fixtures, window frames, retail displays, decorative panels, outdoor signage, reflectors, and colored lenses.

The material is somewhat brittle, so it’s not ideal for applications where high pressure or heavy impacts are involved.

Polycarbonate

Polycarbonate is a more durable, rigid, and impact-resistant alternative to acrylic, known for its industry-leading impact strength. It is 200 times stronger than glass and has decent transparency and clarity.

It exhibits excellent UV-resistant capabilities and density, immune to harsher situations and extreme temperatures.

The material is more expensive than acrylic, but it’s a good option for heavy loads and high-pressure applications that acrylic couldn’t handle.

Polycarbonate suits heavy-duty applications such as lenses, helmets, bulletproof glasses, face shields, safety windows, and containers.

Some prominent applications in the medical field include thermometers, syringes, surgical instruments, blood filters, blood-storing products, drug delivery, and drug potent and delivery systems.

Interesting Read – Antistatic vs. Static Dissipative Plastics | Which One to Choose?

PTFE

Another UV-resistant material with good resistance to light and weathering. PTFE, or polytetrafluoroethylene, is a high-performance fluoropolymer made from carbon and fluorine atoms.

It also exhibits properties like low coefficient of friction, flexibility, good fatigue resistance, low water absorption, anti-adhesion, exceptional chemical resistance, and Low dielectric constant/dissipation factor.

The PTFE applications are in engineering, Chemical, Medical, automotive, electronics, and electrical.

The material is utilized to make seats & plugs, bearings, non-stick surfaces, fittings, valve & pump parts, pumps, diaphragms, impellers, autoclaves, reaction vessels, containers, ligament replacements, heart patches, cardiovascular grafts, electrical insulation, semiconductors, valve stem seals, shaft seals, linings for fuel hoses, gaskets, O-rings, etc.

HDPE

HDPE, or High-density polyethylene, comes from the ethylene family. Apart from having good UV resistance, it is also known for low cost, good impact strength, high melting point, and excellent tensile strength.

It is created by exposing petroleum to extreme heat and pressure. It is one of the biggest manufacturers of thermoplastics out there, thanks to its easy machinability and low cost.

HDPE’s easy moldability, toughness, and low cost make it ideal for packaging applications like jerry cans, drums, fruit juices, crates, bottles, industrial bulk containers, etc. It is also used for consumer goods like pipes, kitchen wares, ice trays, packaging, dustbins, etc.

Other significant applications include industrial uses, cable protection, large inspection chambers, gas, water, and sea downspouts, several applications in commercial vehicles like trucks, cars, and buses, telecommunications cables, and pipes & fittings.

Polyetherimide

Polyetherimide, or PEI, is another UV-resistant plastic used in industrial and mechanical applications.

The high-performance plastic material exhibits high tensile strength, superior heat resistance, chemical stability, outstanding mechanical and electrical properties, flexibility, rigidity, exceptional dimensional stability, high deflection temperature (200°C at 264 psi), and flexural modulus (480,000 psi).

It can be manufactured as both transparent and translucent material.

PEI is mainly used in automotive, industrial, mechanical, and medical applications.

The material excels in heavy-duty industrial applications experiencing extreme temperatures and repetitive pressure.

The typical PEI applications are automotive and aerospace parts, electrical components and covers, heat shields, temperature sensors, and engine components.

Polyphenylene Sulfide

Polyphenylene sulfide or PPS is a semicrystalline high-temprature UV-resistant material known for its opacity and rigidness at a high melting point (280°C).

Yes, it exhibits excellent flame and heat resistance; apart from that, it also has exceptional mechanical strength, dimensional stability, good chemical resistance, and good electrical insulating properties.

The crystalline structure of the plastic makes it solid and durable but also limits it to darker colors. PPS is brittle but blends seamlessly with fibers and fillers to enhance its toughness.

PPS applications are in industrial, automotive, electronics, electrical, medical, and healthcare verticals.

Under-the-hood applications are more prevalent in the automotive sector – thermostat holders, water pump impellers, coolant systems, fuel injection systems, electric brakes, switches, bulb housing, etc.

Polyvinylidene Fluoride

Polyvinylidene fluoride, or PVDF, is a mainstream plastic material that has gained significant popularity in the last decade.

The interest it received is all thanks to its most robust piezoelectric properties compared to any other commercial polymer.

But it also shows great promise for UV resistance, high mechanical strength, exceptional chemical resistance, and good chemical resistance.

Because of the higher cost associated with PVDF is often combined with other cheaper plastics or applied as a thin coating or laminate to enhance metals’ chemical resistance and weatherability, like aluminum and galvanized steel.

PVDF is heavily utilized in aircraft, architectural coatings, electronics, and the chemicals industry.

The most prominent applications include bearings, pump parts, resistant valves, and heat-shrinkable tubing.

How to Improve UV Resistance In Plastics

The range of UV resistance varies among the plastics mentioned above, but incorporating UV-resistant additives or applying protective coatings to the base polymer can enhance their ability to withstand UV radiation.

These coatings, also known as caps, can mitigate photodegradation, improve the appearance of the material, and ultimately extend product lifespan and visual appeal.

There are three primary categories of UV-resistant additives: blockers, absorbers, and stabilizers. Blockers form a protective barrier on the surface of the plastic, shielding it from UV radiation.

Carbon black is a widely-used and potent blocker for outdoor applications, offering approximately 2% UV protection.

Another effective blocking agent is titanium dioxide, a pigment that serves as a UV screening solution.

Absorbers, typically organic compounds, are designed to soak up UV light and release it as a less harmful wavelength, such as heat.

Benzophenones and benzotriazoles are two prevalent absorbers. Benzotriazoles exhibit minimal color impact on materials and can be applied at low concentrations.

They are often used with acrylic and polycarbonate to preserve transparency. Due to their natural vulnerability to UV light, benzophenones are frequently paired with PVC and polyolefins.

In contrast to absorbers, stabilizers employ chemical mechanisms to prevent the breaking of polymer bonds.

These chemicals disperse UV radiation, reducing UV levels that could otherwise damage polymer chemical bonds.

Hindered Amine Light Stabilizers (HALS) are popular stabilizer that converts excited UV reactions into stable chemical reactions.

Plastic UV Resistance Chart

| Plastic Material | UV Resistance Rating | Common Uses | Additives for UV Resistance | Notes |

| Acrylic (PMMA) | High | Skylights, windows, signs | Inherent resistance |

Transparent, good weatherability

|

|

Polycarbonate (PC)

| Moderate | Greenhouses, sunglasses, automotive parts | UV-stabilizers |

Good impact resistance

|

|

Polyethylene (PE)

| Low | Outdoor furniture, playground equipment, containers | UV-stabilizers, carbon black |

Durable, moisture-resistant

|

|

Polypropylene (PP)

| Low | Garden furniture, automotive parts, toys | UV-stabilizers, carbon black |

Lightweight, chemical-resistant

|

|

Polyvinyl chloride (PVC)

| Moderate | Pipes, window frames, siding | UV-stabilizers, TiO2 |

Rigid or flexible, versatile

|

|

Polymethylpentene (PMP)

| Moderate | Laboratory equipment, medical devices | UV-stabilizers |

Transparent, chemical-resistant

|

|

Polyurethane (PU)

| Moderate | Seals, gaskets, insulation, coatings | UV-stabilizers, hindered amine light stabilizers (HALS) |

Flexible or rigid, abrasion-resistant

|

|

Polytetrafluoroethylene (PTFE)

| High | Seals, gaskets, non-stick coatings | Inherent resistance |

Chemically inert, non-stick

|

|

Polyetheretherketone (PEEK)

| High | Aerospace, automotive, medical devices | Inherent resistance |

High-performance, high-temperature resistance

|

|

Polyamide (PA, Nylon)

| Low | Gears, bearings, automotive parts | UV-stabilizers, carbon black |

Strong, wear-resistant

|

FAQs

Below are the frequently asked questions on UV plastic. Let’s dig deep to know more.

Does UV radiation damage plastic?

UV radiation can have a detrimental effect on the plastic part. It can cause a photochemical effect within the polymer structure. Absorbed UV energy can disturb the photons within the plastic and create free radicals that can cause breaks in the polymer bonds.

What makes a plastic material UV resistant?

Blending the material with a UV stabilizer is the best option. UV stabilizers work by absorbing or screening out UV radiation and preventing damage.

What color is most UV resistant?

Plastic with darker colors will remain the most UV resistant. PPS (Polyphenylene Sulfide) is a great example of a plastic material protected by UV rays, and one of the main reasons for that is its naturally dark color.

How long does it take for UV light to break down plastic?

Plastic will be decomposed by UV radiation. And it will take two years to more than 1 million years to decompose it.

Is Nylon UV resistant?

No. But Nylon exhibits excellent wear resistance and good electrical insulating properties.

Suggested Read

- Top 10 High Impact Resistant Plastics

- What are the Top 5 High Tensile Strength Plastics?

- Food Grade Plastic: The Best Plastics for Food Applications

- Top 5 Heat Resistant Plastic Materials | A List of High Temp Plastic Materials

Summary

That was all I had to say for the best UV resistant plastics compatible with your outdoor applications. Tackling UV radiation is a must to save the integrity of the product. UV rays have the ability to damage the molecular chain in a material, breaking apart the molecules and hampering their structural integrity. Thus, using UV-resistant plastics should be taken seriously when needed.

That concludes this article. Wishing you a fantastic day filled with smiles and positivity!

Quick Navigation

Thank you for excellent article. Are any of these materials suitable for application with a UV lamp for air cleaner?

Thanks

I believe they would be suitable. However, I’m not really an expert of air cleaners so I would suggest you to consult with the material supplier about that.

Lovely piece of writing. UV resistant plastics are always difficult to choose from but I think PVC is easily the best.

PVC is indeed a handy material.