What is Compression Molding?

Compression molding is one of the most accepted plastic processing methods on the planet. As the name suggests, It uses excessive heat and large hydraulic presses to make the injected material contact every part of the mold.

First of all, heated molten material is poured inside an open mold cavity. The mold will be closed-in with a top plug and compressed with hydraulic presses.

Thermoset composites are called the best material for processing compression molding. Thermosetting prebags, thermoplastic “organosheets,” Sheet Molding Compound (SMC), and sometimes diced thermoplastic tapes are widely utilized.

The removed component will often be stuck with excessive material, which is called flashing in technical terms. Removing flashing-through blades is important to provide the part an accurate finish.

Let’s quickly dive into the thermoset composite compression molding process. A step-by-step guide –

Thermosets Composite Compression Molding

There are differences between processing thermosets and thermoplastics. Thermosets are often poured cold, and the tool is pre-heated before begging the process.

On the contrary, thermoplastics material is often pre-heated before beginning the process to the required temperature.

#1 First of all, we would need high strength, a two-part metallic tool with similar dimensions to the desired component. After that, the tool will be heated and positioned in a press.

#2 The composite will be pre-shaped in advance into the shape of the tool. Pre-shaping is a significant step that predominantly decides the quality of the finished product.

#3 The pre-shaped part will be positioned into the mold. Here comes the tricky part, as the tool will be compressed under very high pressure.

The pressure ranges somewhere between 900psi to 2000psi and could vary depending on the desired component.

#4 Once the pressure is released, the component will be removed. As I mentioned earlier, flashing could appear on the component’s edges, which should be removed manually.

Also Read – What is a Parting Line? | Parting Line in Injection Molding | Importance of Parting Line

Types of Compression Molding

- Bulk Molding Compound

- Sheet Molding Compound

Bulk Molding Compound

Bulk Molding Compound (BMC), also known as Dough Molding Compound (DMC), belongs to the thermosets composite family. It is a sophisticated blend of many insert fillers, catalysts, stabilizers, pigments, and fiber reinforcements.

Bulk Molding Compound is also stuffed with short fibers to improve stability. Glass reinforcement is also present in BMC and makes somewhere between 10 to 30%. The glass length typically varies around 1/32 and 1/2 inches.

BMC comes in very handy and has multiple applications. It can be formulated in many ways, like flame and track resistance, electrical insulation, supreme mechanical properties, corrosion and stain resistance, color stability, dielectric properties, and flame resistance.

Such high-ranking properties make BMC an excellent option for manufacturing great-quality products with sophisticated designs and geometry.

Regarding availability, BMC can be found in various colors and can tolerate water-based paint quite easily.

Sheet Molding Compound

Sheet Molding Compound (SMC) is another compression molding thermosets compound known for its excellent dielectric` properties, often used for processing components requiring higher mechanical strength.

SMC is also a fiber-reinforced thermoset material. Glass reinforcement is 10% and 60%, and glass length is slightly longer than BMC – between 1/2-inch and 1-inch.

SMC is a blend of insert fillers, polymer resins, pigments, catalysts, stabilizers, release agents, and thickeners.

The manufacturing of SMC is a continuous operation. The material is encased with nylon plastic film to prevent adhesion. Diced glass fibers have been randomly poured onto the paste.

The top film will be introduced, and the sandwich will be rolled out into a predetermined thickness. The sheet will take some to mature (approx. 48 hours).

Supreme mechanical properties and excellent electrical resistance make SMC suitable for complex parts with intricate geometries.

SMC is widely used to manufacture products like business equipment cabinets, automotive body panels, warcraft, and other structural components.

Interesting Read – The Selection of Right Plastic Material | Mechanical Properties | Special Properties | Types of Plastics |

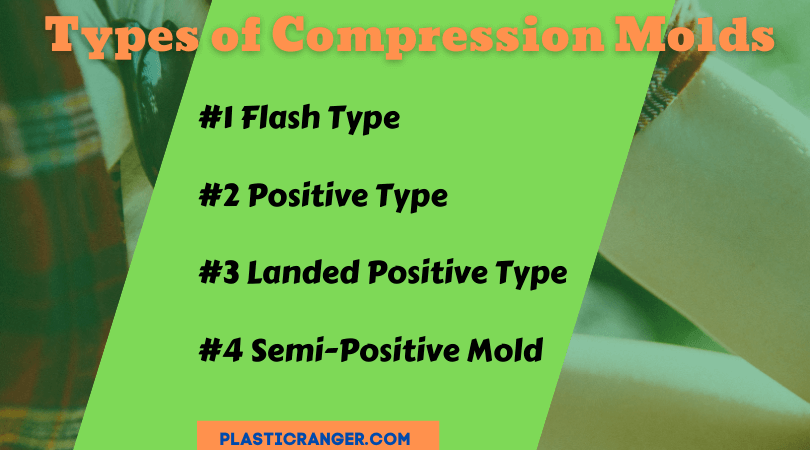

Types of Compression Molds

- Flash Type

- Positive Type

- Landed Positive Type

- Semi-Positive Mold

Flash Type

Flash type mold is the most used compressed mold out there. The reason is its simple construction and ability to hold the component’s thickness within close limits.

As the mold is opened, the excess material will be escaped to the land to form a very thin fin. The escaped flash becomes hard, preventing the escape of the mold charge.

Flash molds are often loaded in volume as the excess material is removed. If material loss concerns you, this mold shouldn’t be your primary choice. However, this mold is the most cost-effective out of all.

Positive Type

Talking about the positive-type mold is equipped with a plunger and deep cavity that compresses the material at the bottom of the mold.

Material loading has to be done accurately, as there is very little material escapement in positive type molds. Positive type molds are useful for manufacturing high-impact materials and components with a deep draw.

Landed Positive Type

This compression mold is quite similar to a positive type mold in terms of design and working, with a subtle difference being a landing placed within the mold to stop the plunger at a pre-determined spot.

More significant loading space helps profess bulky material, which is impossible in the molds mentioned above.

Semi-Positive Mold

This compression mold is a hybrid version of the flash and landed type molds. Apart from flash ridges, the land is also accustomed to restricting the plunger’s travel while the ground takes some of that pressure upwards.

Advantages of Compression Molding

- The main advantage that comes to mind is the prime compression molding plastics. They are stronger, lighter, and resistant to corrosion.

- The ability to manufacture components with intricate designs is one more advantage over other plastic processing methods, Injection molding, and extrusion Molding. The paste is spread properly into the bottom film.

- Thermoset Composites also allow you to manufacture longer fibers than injection molding resulting in stronger and more rigid materials.

- The process is usually slower than other methods when run at a constant temperature; the processing speed increases by the right margin.

- The high-quality matched metals can help in producing components with fantastic surface quality.

- Manufacturers routined to work with metal parts have admitted that they find it easy to transition an object conceptualized for metal to a compression molding part.

- As mentioned earlier, Compression molding has made manufacturing parts with an elaborate design very easy. That unique ability has made it the middle ground between plastic injection molding and laminated compound fabrication.

Disadvantages of Compression Molding

- The method is restricted to manufacturing components with a constant wall thickness.

- Matched metal toolings are a huge expanse if only used for flat moldings. So, it might become baggage for firms with low production volumes.

- The matched metal tooling method can’t make products with individual designs or forms like undercuts without special modifications.

- The press’s capacity and dimensions always decide the upper limits of the component’s size.

Applications of Compression Molding

Compression Molding applications can be seen in many industries like FMCG, aerospace, transportation, and commercial applications.

- Gaskets

- Helmets

- Automotive parts

- cabinets

- Automotive Exterior Panels

Final Words

Thus, was my knowledge and thoughts on Compression molding and compression-molded composites. I hope you like my article. Feel free to comment on your reviews in the comment box.

Peace out!!

Quick Navigation

About the material of the DMC

% of fiber content, types of resin & its % types of hardliners

Internal release agent

Fillers to get desired property in composites