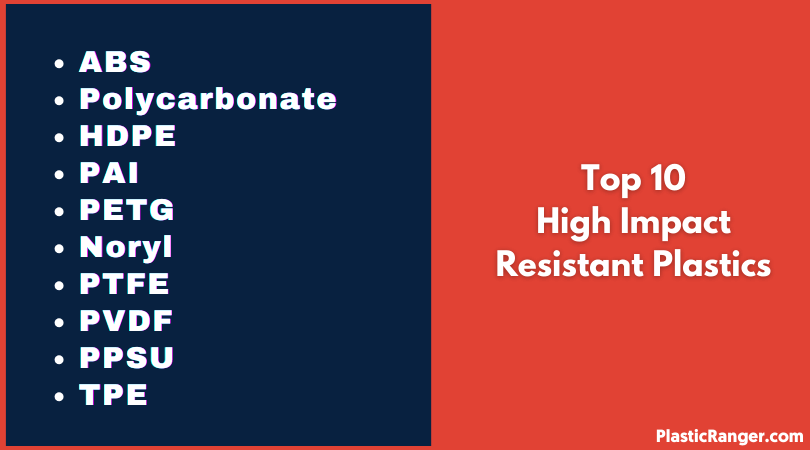

Hey guys, today I’m going to share information about the top 10 high impact resistant plastics.

Plastics have many applications; some are used extensively in heavy industries like industrial, construction, military, and automotive. Those demanding applications require plastics with extraordinary impact resistance and toughness. As the name implies, impact resistance is the ability of a material to withstand both fracture and deformation when subjected to temporary force.

High-impact resistant plastics such as Polycarbonate, ABS, UHMW, and PPSU have fantastic toughness and offer unique benefits hard to find in metals, allowing them to perform in challenging circumstances. They are often called the most robust plastic materials.

It is also important to note that the impact resistance of plastic material is highly temperature-dependent. That makes choosing the right end-use temperatures extremely important.

Top 10 High Impact Resistant Plastics

- ABS

- Polycarbonate

- HDPE

- PAI

- PETG

- Noryl

- PTFE

- PVDF

- PPSU

- TPE

ABS

ABS is an amorphous thermoplastic that is also opaque. It is one of the most rigid thermoplastics, with applications in automotive parts, toys, electrical and electronic components, and even appliances. Apart from having extraordinary impact resistance, it also can maintain toughness in low temperatures.

Other salient features are good mechanical strength, low cost, good weldability, decent insulating properties, outstanding corrosion resistance, excellent surface brightness, great abrasion resistance, sturdy structure, and excellent resistance to dilute acid and alkalis; low melting also helps in easy usability for injection molding and 3D printing.

A few limitations would be poor weathering resistance, meager resistance for solvents like ketones, esters, and aromatic, and poor UV resistance without protection.

Fabulous Read – Top 5 Heat Resistant Plastic Materials | A List of High Temp Plastic Materials

Polycarbonate

Polycarbonate is also known for its outstanding impact strength and rigidity. Another convenient attribute of polycarbonate is that it is transparent. Because of its incredible toughness, it is often used as an alternative to glass for both lightweight (sunglasses and skylights) and heavy applications (Bulletproof glasses and protective gear).

The typical applications for polycarbonate also fall in the same bracket. It is extensively used in applications where transparency and high impact resistance are a priority – DVDs, automotive components, protective gear, Blue-rays, eyewear, greenhouses, medical devices, etc.

Some salient features of polycarbonate are stability in toughness even at -20°C, excellent mechanical retention at up to 140°C, good steam sterilization resistance, easy weldability, processability, great abrasion resistance, and good flame retardancy.

Certain drawbacks with polycarbonate are readily affected by chemicals like hydrocarbons and bases, low fatigue tolerance, and proper during is a must before processing.

The most popular polycarbonate variants include Lexan® by SABIC or Makrolon® by Bayer MaterialScience.

| Property | Value |

| Density | 1.20 – 1.22 g/cm³ |

| Tensile Strength | 55 – 75 MPa |

| Melting Point | 155°C (311°F) |

| Impact Strength | 600 – 750 J/m |

| Yield Strength | 55 – 75 MPa |

| Hardness | 75 – 80 Rockwell M |

| Fracture Strength | 1.9 – 2.3 kJ/m² |

HDPE

HDPE, or high-density polyethylene, comes from the polyethylene family, boasting excellent impact and tensile strength, high melting point, and low cost. It is used to make products like consumer goods such as ice trays, dustbins, food packaging, etc. Packaging applications like bulk containers, bottles, crates, etc. Wires, Cables, and Pipes for drainage, cable protection, industrial uses, large inspection chambers, gas, water, sea downspout, etc.

Besides having excellent impact strength, HDPE has an extraordinary strength-to-density ratio of 0.93 to 0.97 g, easy malleability and moldability, corrosion resistance, and is easily recyclable. However, high flammability and high thermal expansion can be a drawback.

Below are the mechanical properties of HDPE:

| Mechanical Properties | ||

Tensile Strength, Yield at 23 C | MPa | 23.0 – 29.5 |

Tensile Strength, Break at 23 C | MPa | 30.5 – 33 |

Tensile Modulus at 23 C | MPa | 900 – 1550 |

Flexural Modulus | MPa | 970- 1380 |

Flexural Strength, Yield | MPa | – |

Izod Notched | J/m (kJ/m2) | 71 – 159 (20) |

PAI

PAI or polyamide-imide, also known as (Torlon®), is high-impact strength, stiff, and rigid plastic material that can remain dimensionally stable in elevated temperatures where other thermoplastics lose their mechanical properties. Parts made from PAI will show high impact strength, compression, and tensile strength, ensuring good mechanical loading capability.

Torlon® is also known for its high thermal stability, good chemical resistance, and supreme wear properties in temperatures up to 275°C., good machinability, excellent heat defecation temperature, excellent coefficient of thermal expansion, and outstanding tribological and wear performance.

PAI is generally found in aerospace components, semiconductor machinery, and pump and valve parts.

Engaging Read – 7 Best UV Resistant Plastics For Outdoor Applications

PETG

PETG, also known as polyethylene terephthalate glycol, is a clear copolymer and thermoplastic with very good impact resistance, excellent durability, moldability, and chemical resistance. It’s a more profound variation of PET (Polyethylene terephthalate) with low molding temperatures making it extremely easy to mold, heat bent, and vacuum form into various geometries.

It boasts excellent impact resistance on par with ABS. Still, cost-effective and has good thermal stability, outstanding chemical resistance, and a fast thermoforming cycle – the brake is formable up to 0.080″ thickness and has fewer overheating issues than PET.

Regarding some limitations, PETG is susceptible to scratches, poor moisture resistance, parameter inaccuracies, and environmental problems.

Below are the general properties of PETG:

| General Properties | ||

| Density | 0.0455 – 0.0462 | lb/in^3 |

Tensile Strength | 8.7 – 9.57 | KSI |

Yield Strength | 6.95 – 7.67 | KSI |

| Elongation | 102 – 115 | % strain |

Impact Strength | 90.4 – 95.2 | ft.lbf/in^2 |

| 0.292 – 0.306 | 10^6 psi | |

Fracture Strength | 1.92 – 2.31 | KSI/in^0.5 |

Impact Strength | 90.4 – 95.4 | ft.lbf/in^2 |

| Hardness | 14.4 – 15.9 | HV |

Noryl

Noryl is a batch of modified resins comprising amorphous blends of polyphenylene oxides (PPO) or polyphenylene ether (PPE) resins with polystyrene. It was originally developed by General Electric plastic in 1966. The company was later acquired by SABIC, which now owns the Noryl trademark.

The salient features of Noryl include excellent impact resistance, high heat resistance, good electrical insulation properties, affordability, excellent hydrolytic stability, good processability, low density, and outstanding dimensional stability.

Because of Noryl’s good mix of mechanical and chemical properties, it is suitable for various electronics, machinery, coatings, and electrical equipment applications. It has also been speculated that Noryl can replace polycarbonate in making Blu-ray Discs.

One of the most popular Noryly applications was the molded case of the original Apple II computer.

PTFE

PTFE, or polytetrafluoroethylene, is a high-performance, versatile fluoropolymer made of carbon and fluorine atoms. It is known for its good impact resistance and outstanding electrical insulating properties. It is generally available in three forms – granule, water-based dispersions, and fine powder.

Other salient PTFE properties are chemical inertness, low coefficient of friction (static 0.08 and dynamic 0.01), great high and low heat resistance, excellent chemical resistance, outstanding dielectric constant, and insulating pressure.

Certain drawbacks associated with PTFE are low radiation resistance, creep and abrasive sensitivity, and corroding to toxic fumes.

PTFE makes numerous products in various industries like engineering, chemicals, automotive, medical, and electrical & electronics. Some common applications are non-strick surfaces, plugs, fittings, impellers, autoclaves, flexible printed circuit boards, electrical insulation, etc.

| Property | Value |

| Density | 2.15 – 2.3 g/cm³ |

| Tensile Strength | 25 – 45 MPa |

| Melting Point | 327°C (621°F) |

| Impact Strength | 13 – 20 kJ/m² |

| Yield Strength | 15 – 20 MPa |

| Hardness | 50 – 65 Shore D |

| Fracture Strength | 7 – 10 MPa/m |

PVDF

Another fluoropolymer is PVDF, or Polyvinylidene Fluoride, a semi-crystalline, highly inert, rigid, and stable thermoplastic fluoropolymer. Apart from having good impact resistance, it boasts good thermal stability, high crystallinity, and excellent chemical resistance.

It is also the third-best radiation-resistant plastic in the market, only behind PEEK and polyamide.

Its applications include electrical and electronics applications such as high-temprature wirings, home appliances, and industrial power control systems. Filtration equipment, like housings, filters, membranes, etc., are also made from PVDF.

| Properties | Values | Units |

| -220°C | – | |

Tensile Strength @23°C | 50 | Mpa – ASTM – D638 |

Thermal Consuctivity@23°C | 0.2 | W/m.k – ASTM C177 |

Impact Strength | No Break | – |

| 338-347 | deg F | |

| 20-25@ 1mm thick | kV.mm – ASTM D149 | |

Elongation at Break @23°C | 0.4 | ASTM-D1894 |

Continues working temperature | 150 | °C |

Weathering resistance | Excellent | – |

Coefficient of friction | 0.4 | ASTM-D1894 |

Limiting Oxygen Index | 44 | % |

PPSU

Polyphenylsulfone, or PPSU, is a high-performance, amorphous, heat resistant, and transparent polymer. It is known for high impact resistance, flexural and tensile strength, chemical resistance, and hydrolytic stability. It has superior mechanical properties but is utilized very little compared to other thermoplastics owing to the high cost.

PPSU is an excellent choice for parts exposed to high temperatures and corrosive environments. Examples are medical device parts, automobile parts, pipe fittings, battery containers, aerospace, and nursing applications. Polyphenylsulfone has no melting point because of its amorphous nature and exhibits tensile strength up to 55 MPa (8000 psi).

It has supreme thermal and mechanical properties, but most unfilled grades are unsuitable for outdoor applications because of poor UV, ozone, and weathering resistance.

Interesting Read – How to Choose the Right Lubricants For Plastic Parts?

TPE

TPE or Thermoplastic Elastomers is a blend between rubber and thermoplastics. Thus it consists of both thermoplastic and elastomeric properties. It exhibits good impact strength by resisting low and high temperatures (-30d°C to +150°C), with good thermal properties and material stability.

Some advantages include outstanding flexural fatigue resistance, good electrical properties, muscular tear and abrasion resistance, high impact strength and elongation, low specific gravity, exceptional resistance to weathering and chemicals, and recyclability.

TPE’s are commonly used in the automotive industry, medical applications, roofing materials, and, most importantly, shoe soles. It also shows rapid heating, ventilation, and air conditioning adoption.

Some typical applications of TPE are Cables & Wires, grip & handles, Plugs & Seals, and Power & Hand Tools.

| Property | Value |

| Density | 0.9 – 1.3 g/cm³ |

| Tensile Strength | 10 – 30 MPa |

| Melting Point | -50 to 130°C (-58 to 266°F) |

| Impact Strength | 20 – 80 kJ/m² |

| Yield Strength | 10 – 30 MPa |

| Hardness | 20 – 95 Shore A |

| Fracture Strength | 10 – 80 kJ/m² |

FAQs

Below are the frequently asked questions on the strongest plastic materials. Let’s dig deep to know more.

How to improve a plastic material’s impact strength?

There are three main methods often used by manufacturers to improve or enhance a plastic’s impact strength:

- Copolymer Addition – Modified during the synthesis of plastic polymers. Here we’re bonding long carbon chains or materials with bonds of soft molecular structure that can be bonded to the main chains of polymer, effectively lowering the Tg temperature of plastic polymers. That will enhance the impact resistance at room and low temperatures but compromise the plastic’s tensile strength and modulus.

- Polymer Blending – Add an impact modifier to plastic polymers with insufficient impact resistance and disable them with a twin-screw extruder. Generally, thermoplastic elastomer or rubber is chosen as a type of impact modifier.

- Addition of glass fibers -Glass fibers are generally coated with silane surface coating to enhance the bonding force between the glass fiber surface and plastic polymers.

Which are the 7 types of plastics?

Below are the 7 types of plastics:

1) Polyethylene Terephthalate (PET or PETE)

2) High-Density Polyethylene (HDPE)

3) Polyvinyl Chloride (PVC or Vinyl)

4) Low-Density Polyethylene (LDPE)

5) Polypropylene (PP)

6) Polystyrene (PS or Styrofoam)

7) Other.

Which are the two main types of plastics?

The two main types of plastics – Thermoplastics and Thermosets.

Which is the most commonly used plastic in the world?

Polyethylene is the most common plastic in the human world, with more products than other plastic materials worldwide. The main reason for that is all its forms – HDPE (High-Density Polyethylene), LDPE (Low-Density Polyethylene), and LLDPE (Linear Low-Density Polyethylene) are used in many applications throughout several industries worldwide.

Which is the softest plastic material?

LDPE is the softest plastic material. It has a very low density and thus is often considered the go-to material for packaging applications.

Final Thoughts

The top 10 high-impact resistant plastics offer distinct advantages across various applications, including automotive, aerospace, and medical devices. Polycarbonate, ABS, and PEEK stand out for their blend of toughness and ease of processing. Newer, specialized materials like UHMWPE and PVDF offer additional properties such as chemical resistance.

However, materials like Polyamide-imide and PPSU offer a balance of heat and chemical resistance. Matching the plastic to the specific mechanical and environmental conditions required for optimal performance is crucial. Given the progressive advances in polymer technology, one should also remain open to emerging high-performance options.

Kindly share your views and questions in the comment box.

Have a fantastic day.

Quick Navigation

Respected sir,

Its kindly requested to suggest me the 05 best impact strength plastics among the above 10 given. I need it to use as an energy absorber to minimize the impact damage during crash load.

I believe you can pick any five out of the list. It’s a comprehensive list made after a lot of research. Still, the best option is to consult with your material supplier.

I have found, by smashing different types of plastic with a hammer, that TPE has the best impact resistance out of the ones I tested. I tested ABS, PET, TPE, PE, and PP. Most tore and got squashed, PET shattered, and TPE bounced it off like nothing happened.