Hello people, I will share an integrating guide on shore hardness scales – the most reliable measurement method to determine plastic’s hardness. So without further ado, let’s get started.

What is Shore D Hardness Scale?

The Shore D hardness test, aka the durometer test, existed so people could have a standard reference when discussing materials.

There are several scales made for discussing different materials. The test is mainly utilized when the materials are too soft for the Rockwell test.

Materials with a very soft texture, like rubber and TPE, should be tested with Shore D.

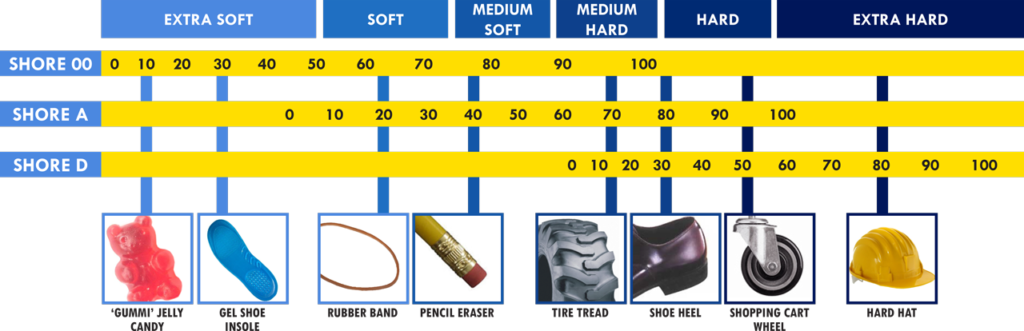

There are three most popular Shore hardness scales:

Shore 00 – Used for measuring gels and rubbers that are very soft.

Shore A is used to measure the hardness of flexible mold rubbers that range from very soft and flexible to somewhat medium flexible to hard with no flexibility whatsoever. Often, semi-rigid plastics are also measured on the high end of the Shore A Scale.

Shore D – Utilized to measure the hardness of semi-rigid plastics, hard rubbers, and hard plastics.

How Does the Shore Hardness Test Work?

A spring-loaded needle is kept under the plastic in Shore hardness, and pressure is registered. Once the needle is pierced as far as possible, the depth of indentation of the needle is measured, proportional to the plastic’s hardness.

ASTM D2240 and ISO 868 are the test methods used for measuring Shore D hardness

Shore hardness measures are dimensionless, which comes between 0 to 100. The higher the number harder the material.

The resulting penetration is dependent on the following factors

- Material hardness

- The shape of the indenter

- Its viscoelasticity

- Duration of the test

Fascinating Read – What is Processing and Drying Temperatures of Plastics

Below is a table with typical Shore D hardness values:

Shore Hardness Chart

| Material | Minimum Value |

Maximum Value

|

| 100 | 100 | |

|

ABS – Flame Retardent

| 80 | 90 |

|

ABS – High Heat

| 80 | 85 |

|

ABS – High Impact

| 75 | 85 |

| Acetal | 80 | 95 |

| Acrylic | 90 | 99 |

|

CA – Cellulose Acetate

| 50 | 95 |

|

CAB – Cellulose Acetate Butyrate

| 60 | 90 |

|

ETFE – Ethylene Tetrafluoroethylene

| 70 | 75 |

|

EVA – Ethylene Vinyl Acetate

| 15 | 45 |

| 60 | 70 | |

|

HIPS – High Impact Polystyrene

| 60 | 75 |

| 40 | 50 | |

|

LLDPE – Linear Low-Density Polyethylene

| 55 | 56 |

|

Polyamide 11 30% Glass fiber reinforced

| 73 | 78 |

|

Polyamide 11 conductive

| 64 | 64 |

|

Polyamide 11 flexible

| 59 | 63 |

|

Polyamide 11 rigid

| 64 | 72 |

|

Polyamide 12 conductive

| 71 | – |

|

Polyamide 12 fiber reinforced

| 70 | 80 |

|

Polyamide 12 flexible

| 63 | 63 |

|

Polyamide 12 glass filled

| 58 | 75 |

|

Polyamide 12 rigid

| 68 | 72 |

| 90 | 95 | |

| 90 | 95 | |

|

PCTFE – Polymonochlorotrifluoroethylene

| 75 | 85 |

| 70 | 80 | |

| 85 | 95 | |

|

PEI – Polyetherimide

| 95 | 99 |

| 85 | 95 | |

| 70 | 80 | |

|

Polypropylene – Homopolymer

| 70 | 83 |

|

Polystyrene crystal

| 85 | 90 |

|

Polystyrene – High heat

| 90 | 95 |

| 50 | 65 | |

| 65 | 82 | |

|

SAN – Styrene Acrylonitrile

| 75 | 95 |

|

Thermoplastic Starch

| 52.4 | 53.6 |

|

XLPE – Crosslinked Polyethylene

| 30 | 80 |

What does Shore Hardness Mean for a Manufacturer?

Durometer scale hardness or Shore D hardness, which mold rubber should be used to mold a specific component or part.

Now, the question is, how seamlessly will you be able to remove the original model from the mold once it is cured?

As a manufacturer, one needs to understand the material has with specific hardness for your application. For example, you wouldn’t choose rubber or a material with a durometer of 70A to make a product that is supposed to be flexible.

A 70A material is hard and stiff and wouldn’t provide enough flexibility to remove the part without breaking it.

A wiser choice would be a Shore 30A material offering enough flexibility to remove the part quickly.

Another excellent example of that phenomenon is the case of manufacturing a gasket for a high-pressure application; the manufacturer would require a material with a higher Shore hardness to withstand the pressure and avoid any leaks.

Alternatively, if they manufacture a seal for a low-pressure application, a material with a lower Shore hardness may be more suitable to ensure proper compression and effective sealing.

The Shore hardness measurement aids manufacturers in maintaining the consistency and quality of their products.

By assessing the hardness of materials at various stages of the manufacturing process, they can detect any variations and make appropriate adjustments to sustain consistent quality.

Effect on Product Performance and Quality

The Shore hardness or durometer scale of a plastic material can significantly affect the performance and quality of a product.

Typically, materials with higher Shore hardness offer better resistance to wear and tear, making them suitable for high-stress applications.

Such materials are also less prone to deformation under pressure or stress, thus ensuring consistent performance over extended periods.

On the other hand, materials with lower Shore hardness are generally more flexible and easier to manipulate, making them suitable for applications that require bending or stretching.

However, these materials may be more susceptible to wear and tear and may not withstand stress or pressure as well as harder materials.

FAQs

What is hardness measured in?

The SI unit of hardness is N/mm². The unit pascal is also often used for hardness. However, hardness should never be confused with pressure. Different hardness has different scales of measurement. Therefore, the units are not suitable for direct comparison.

What is a Durometer?

A durometer or Shore Durometer is a standard way to measure the hardness of materials like plastics and rubbers.

Durometer measurement scales range from 0 to 100, but there is no such thing as a durometer unit of measurement. In layman’s terms, a durometer is a dimensions measurement.

What is the difference between Shore A and Shore D?

The major difference between the Shore A hardness scale and Shore D is that the former measures softer rubbers (including thermoplastic rubber). The latter is used for measuring harder, more rigid materials.

What is the difference between Shore and Rockwell hardness testing methods?

As mentioned earlier, Shore A and Shore D testing methods measure hardness in flexible and semi-flexible materials. In contrast, the Rockwell hardness method is generally chosen for ‘tougher’ plastics such as polycarbonate polystyrene, nylon, and acetal.

Which is the strongest plastic in the world?

Going by the terms of the durometer scale, Polycarbonate is the strongest plastic globally in terms of strength, durability, and impact resistance. It is 200 times stronger than glass and is warranted against cracks and breakage.

Suggested Read

- What is the Density of Plastics? | The Complete Guide

- 7 Types of Plastics | An Helpful Illustrated Guide

- 6 Best Plastic Molding Techniques | A Complete Analysis

- Food Grade Plastic: The Best Plastics for Food Applications

The Takeaway

That was my take on the Shore hardness scale and all its attributes. It is an essential measurement for determining the resistance of a material to indentation and penetration.

The Shore hardness scale offers a convenient way to compare the hardness of various materials and ensure that the appropriate material is selected for a given application.

Understanding the Shore hardness scale can help you make informed decisions about material selection and product design, whether you are working with rubber, plastics, or other materials. By leveraging this critical measurement, manufacturers can produce high-quality products that meet the needs of their customers and outperform the competition.

Kindly share your thoughts and questions in the comment box.

Quick Navigation

hi, i want to make a mold of a roman temple of the winds capital which sets on my concrete columns. It is a ten inch capital. What is recommended as a compound to pour over this capital and also hold the concrete poured into it. Any suggestions?

Hi there,

I was just wondering if there is a certain range of Shore A hardness that is best for different types of plastics. I’ve heard that Shore A is good for flexible plastics, but is there a range for more rigid plastics?

Thanks!