What are The Best Plastic Molding Techniques?

Plastic Molding is manufacturing plastic parts by pouring liquid plastic into a mold. There are different methods used for molding plastics. The six most common molding methods are Injection Molding, Extrusion molding, Blow Molding, Compression Molding, Rotational Molding, and thermoforming.

Depending on the method used, various factors like heat, pressure, cooling, melting point, mold temperature, and many other factors are considered for optimum quality results.

Here we will discuss all six primary plastic molding methods in detail. So without further due, let’s get started.

Injection Molding

Injection molding is undoubtedly the most common plastic molding manufacturing method on the planet. Here the molten fluid is created by heating the solid granules above their melting point. The liquid resin created by heating has a low resistance to flow. It is considered the best option of all for large-scale industrial manufacturing.

Talking about the process, the liquid material will first be poured into the mold to shape the material to the correct size and aesthetics of the mold. The material is kept inside till the time it cools. Once cooled, it will be injected into a heating chamber, and finally, the part will be ejected.

Salient Features of Injection Molding

- Injection molding is a versatile, quick, and efficient method for large-scale production.

- It’s fast but capable of producing parts with intricate designs and complicated geometries.

- It gives exceptional accuracy with all parts produced. Even if you produce a thousand parts, they will look identical without inaccuracies.

- Products can be made with increased flexibility, giving designers and engineers exceptional freedom to create innovative designs constantly.

- Low operating and maintenance costs.

- Injection molds are heavy and complex, so they might be heavy on the wallet initially, but if you’re producing in bulk, the price per cost will be very economical.

Extrusion Molding

Extrusion molding is utilized to produce long and straight parts. Hot melted plastic is pressed through a hole called Die to create the desired shape. The cross-sections vary and can be shaped according to one’s needs – the common shapes are solid round, rectangle, L-shapes, and T-shapes.

It uses compressive stress and tensile strength to shape and deform the material. It is also highly compatible with mostly all thermoplastics but works best with material contacting high strength and stiffness.

Salient Features of Extrusion Molding

- Suitable for high volume production, maintaining a good speed and quality.

- It’s very cost-effective. The waste can be recycled multiple times without trading off with quality, and even the machinery itself is tough and can run for 24 hours a day without adding extra costs to maintenance.

- It allows manufacturers to produce flexible products with consistent cross-sections.

- Overall operating costs are also low thanks to the reasonably simple machinery design.

- An advantage it gives over any other molding process is the freedom of post-extrusion alterations in the products while still warm.

Blow Molding

Blow molding is an optimal process for producing hollow, thin-walled plastic parts. This is a relatively simple method used mainly when having a uniform wall thickness is a priority. It all starts with molten material being poured through parison.

Parison is a tube-shaped plastic structure with holes that pass compressed air through it. The parison is created when the molten material is pushed through an extruder.

The machine heats the plastic material until it liquefies and injects air into it to form a balloon-like shape. The plastic is blown into the mold and becomes more prominent in size; it presses against the mold walls and begins taking the desired shape. After the liquid balloon enters the mold, it cooled to maintain its shape.

Salient Features of Blow Molding:

- Super-fast production cycle. It can produce hundreds of thousands of hollow parts within a short period. It can produce about 1400 pieces (The number can significantly change depending on the product being produced) in around 12-hour work time.

- The overall processing cost of machinery and tools are meager. So it has become a go-to option for small and medium enterprises.

- Single or multiple external threads can be added without any problem.

- It’s also very versatile in terms of applications. It is often used for producing drums, plastic bottles, containers, cases, fuel tanks, etc.

- Customizations are also accessible, making it a lucrative option for the food and pharmaceutical industries.

Compression Molding

Compression Molding uses excess heat and hydraulic presses to heat and contact molten material to every mold corner. To begin, heated molten material will be poured into an open mold cavity. The mold will close in with a top plug and compressed hydraulic presses to get the desired shape.

High temperature is maintained throughout the entire process to ensure the high strength of the final product. The process is completed by cooling the molten material and holding its shape before being trimmed and removed from the mold.

Thermoset composites are the most suited materials for compression molding.

Salient Features of Compression Molding

- The molding method is used for producing plastic parts replacing metal. The main reason behind that is the product’s strength, lightweight, durability, and corrosion resistance.

- Thermoset composites can produce longer fibers, producing more robust and rigid products.

- Parts have extraordinary surface quality.

- This plastic molding can also produce parts with complex geometries if the paste is appropriately spread in the bottom film.

- Compression molding is often the middle ground between plastic processing and compound metal fabrication.

- Manufacturers regularly working with metal fabrication have admitted that they easily transition a component imagined for metal to a compression molding part.

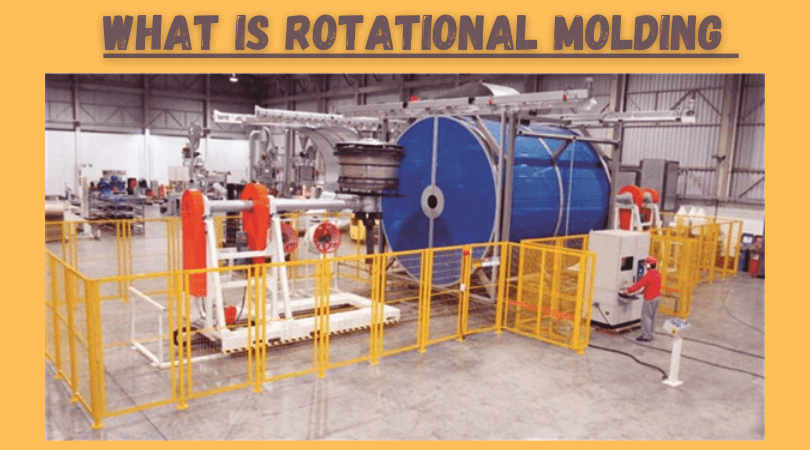

Rotational Molding

Rotational Molding, better known as rotomolding is a plastic molding technique compatible with producing one-piece hollow components. It doesn’t involve pressure, and even the molds are inexpensive as they can’t resist pressure making it ideal for short production runs of 2000-3000 units a year.

The method involves molten material poured inside the mold and rotating it at high speeds. The materials then evenly spread and cover the entire surface of the mold to create a sizeable hollow part with evenly thick walls.

Rotmomolding is a casting technique, so the material is poured in powder form instead of granules form like other methods. Polyethylene is the most utilized (About 97%) thermoplastic material for rotational Molding as it can be grinded easily.

Salient Features Of Rotational Molding

- Apart from giving designers and engineers exceptional freedom in design, rotomolding also easily supports other production intricacies like ribs, fixtures, inserts, surface textures, etc.

- Cost-effectiveness and the fact that it produces a low number of units make it ideal for small business owners and start-ups.

- Low upfront setting-up costs.

- Products have uniform wall thicknesses with straight and thick corners, mostly in all the production runs.

- There is no limit regarding the size of the part being produced. That’s why rotomolding is ideal for producing tanks, plastic boats, shopping cart accessories, etc.

Thermoforming

Thermoforming is a plastic molding technique in which a thermoplastic sheet is heated to a specific temperature making it flexible and soft. Then the sheet is stretched and pressed into a vacuum or compressed air pressure to form the desired shape. Adequate cooling plays a key role in manipulating the sheet.

Thermoforming utilizes very low pressure, so the molds are very inexpensive. Thermoplastics like PET, Polypropylene, HDPE, acrylic, and polycarbonate are the most compatible with thermoforming.

Salient Features of Thermoforming:

- Very flexible to consumer needs regarding complexity, size, and other attributes.

- Developing a new prototype will be easier and faster in thermoforming than other methods.

- Its excellent production efficiency can save significant time and resources, which can be utilized for other things.

- Many customization options are available for this molding method, with skyrocketing customer satisfaction rates.

- The thin-gauge thermoforming method produces lids, blisters, trays, containers, clamshells, disposable cups, etc.

Engaging Read – Physical Properties of Plastic Materials | The Complete Guide

FAQs

What is the difference between Molding and casting?

Molding is an act of creating a cavity form that has a reverse impression of an original model. On the other hand, casting is pouring molten liquid material into the mold’s cavity. After some time, this liquid will cure by a chemical reaction or cooling.

How many types of Moulding machines are there?

There are main molding machines – 1) Squeezers, 2) Jolt Machines 3) Sand Slingers.

How many types of injection Molding are there?

There are 6 different types of injection molding technologies – 1) Thin Wall Molding, 2) Gas-assisted Injection Molding, 3) Metal Injection Molding, 4) Liquid Silicone Injection Molding, 5) 3D Printing, 6) Unique Material Formulations.

What are some common Injection molding defects?

The common injection molding defects are as follows:-

- Warping

- Flow lines

- Burn marks

- Sink marks

- weld lines

- Vacuum voids

Is Blow Moulding expensive?

Blow molding is a relatively inexpensive process compared to injection molding. Machinery is cheaper and has a one-piece constructed setup, so overall setting up cost is reasonable.

The Takeaway

In conclusion, plastic molding techniques have come a long way, with technological advancements allowing for increased precision and efficiency.

Each technique has unique advantages and applications, from injection molding to blow Molding to thermoforming. By understanding the differences between these six molding techniques, manufacturers can choose the best option for their specific needs, resulting in high-quality products that meet customer expectations.

I hope you find my work satisfactory. Please feel free to leave your feedback in the comments section.

Wishing you a wonderful week ahead!

Quick Navigation

The world appreciates the writings that include the knowledge and information about everyday science. I like your style and promise to come again and again to increase my skills and knowledge.

Thank you very much 🙂

Excellent article. Many thanks to author for sharing useful info in concise and precise manner.

I appreciate the feedback. Thank You.

Great blog post.Helpful and informative tips. I like it thanks for sharing this information with us

Thank you very much 🙂

Thanks for helping me understand that molding of plastic would be made by creating a cavity form where a reverse impression of the original model would be done. I guess this process will be able to offer a custom plastic fabrication service to clients who might need it. The clients can use this to create the containers or even the actual products they will offer to the market.

That’s an interesting insight