Hello mates, today I will talk about a very intriguing topic, the hardness of plastic materials. A material’s hardness is essential in determining its applicability. So without further ado, let’s get started.

What is the Hardness Of Plastic?

Plastic hardness means its resistance to permanent indentation of plastic by a stronger body.

The typical nature of plastics is the softer material is scratched or worn by the more complex material.

It is one of the most measured attributes and is often reported in the technical sheets of plastics.

Analyzing hardness parameters is seen primarily in industrial parts and construction devices.

The effect is more evident when scratching or losing surface texture from stroking or rubbing two materials.

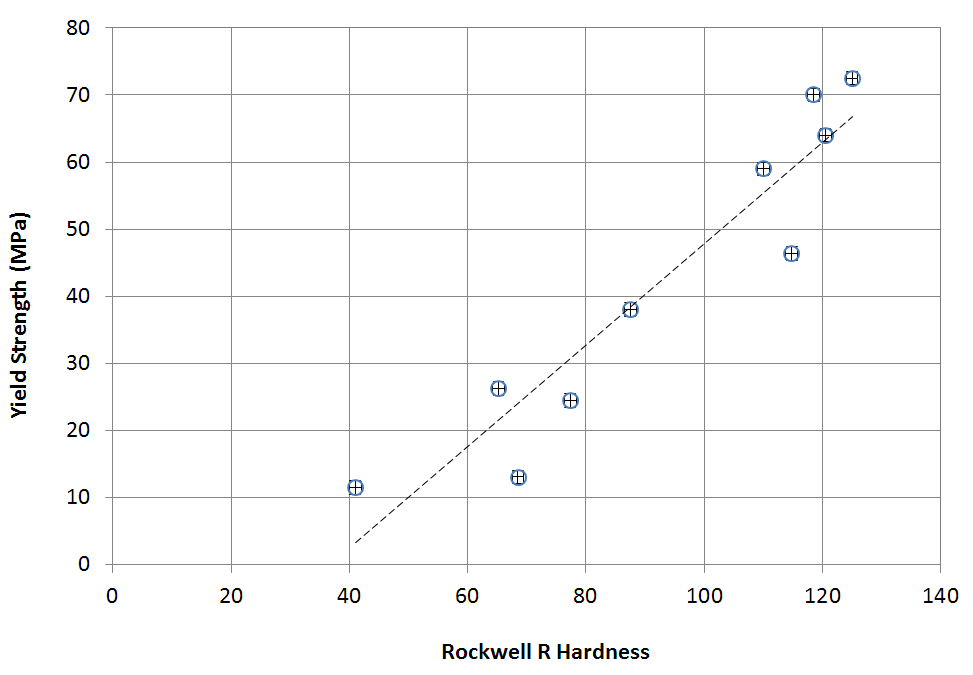

Hardness is essential to their basic properties, specifically in ductile plastic materials. In yield and tensile strength, a plus-minus linear correlation is observed (The flowing image will make it more evident).

However, an essential factor is that the hardness is not always a good indicator of other properties like abrasion to wear, strength, and scratch resistance.

Hence, it should not be considered alone for product design.

Source - Polymerdatabase.com

How to Measure Hardness?

ISO 2039-1:2001 — This standard establishes the measurement of plastic hardness using the ball indentation method.

ISO 2039-2:1987 — The hardness of plastics is determined by this standard, employing the Rockwell hardness scale.

ISO 7619-1:2010 — The shore hardness scale is utilized to determine the indentation hardness of vulcanized rubbers and thermoplastics, as specified in this standard.

ASTM D785-08(2015) — The hardness of plastics and electrical insulating materials is determined using the Rockwell hardness scale, as outlined in this ASTM standard.

ASTM D2240-15(2021) — This ASTM standard specifies the rubber hardness measurement using the durometer.

Several verifiable hardness scales have been developed to test and analyze hardness.

They are well equipped to replicate scratching, rubbing, and wear between two materials.

These techniques provide a corresponding ranking of the hardness of two polymers.

Two mainstream methods to measure hardness are the Rockwell and the Shore methods.

The Rockwell hardness tests harder materials like polycarbonate, polystyrene, and polyamide.

On the other hand, the Shore method is used for testing elastomers, rubbers, and softer materials like polypropylene, polyethylene, polyvinyl chloride, etc.

The Rockwell Hardness method begins with a sample with at least 6.35 mm smacked by a hard steel ball.

A small pre-stressing will be applied; the apparatus will be riveted, then a more enormous load will be registered and removed.

After some time, the pre-stressing is still registered the remaining indentation is read from the scale.

The method uses different steel balls and weights depending on the material and scale. E, M, and R are the most common Rockwell scales utilized for plastics.

Coming to Shore hardness, a spring-loaded needle is kept under the plastic, and pressure is registered.

Once the needle is pierced as far as it can be, the depth of indentation of the needle is measured, which is proportional to the hardness of the plastic.

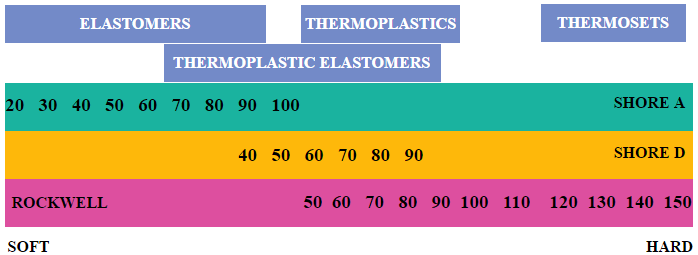

There are many hardness scales for measuring plastic hardness. The most popular ones are Shore A and Shore D.

The Shore A scale is chosen when testing very soft gels and rubbers. On the other hand, shore D is preferred when testing hard rubbers, semi-rigid plastics, and hard plastics.

The deepness of the indentation depends on multiple factors, such as hardness, viscoelastic properties, the geometry of the indenter, and the duration of the test.

General Shore D Hardness Values

Below is the table with typical Shore D hardness values for all the mainstream plastic materials.

| Material | Minimum Value | Maximum Value |

| ABS – Acrylonitrile Butadiene Styrene | 100 | 100 |

| ABS – Flame Retardent | 80 | 90 |

| ABS – High Heat | 80 | 85 |

| ABS – High Impact | 75 | 85 |

| Acetal | 80 | 95 |

| Acrylic | 90 | 99 |

| CA – Cellulose Acetate | 50 | 95 |

| CAB – Cellulose Acetate Butyrate | 60 | 90 |

| ETFE – Ethylene Tetrafluoroethylene | 70 | 75 |

| EVA – Ethylene Vinyl Acetate | 15 | 45 |

| HDPE – High-Density Polyethylene | 60 | 70 |

| HIPS – High Impact Polystyrene | 60 | 75 |

| LDPE – Low-Density Polyethylene | 40 | 50 |

| LLDPE – Linear Low-Density Polyethylene | 55 | 56 |

| Polyamide 11 30% Glass fiber reinforced | 73 | 78 |

| Polyamide 11 conductive | 64 | 64 |

| Polyamide 11 flexible | 59 | 63 |

| Polyamide 11 rigid | 64 | 72 |

| Polyamide 12 conductive | 71 | – |

| Polyamide 12 fiber reinforced | 70 | 80 |

| Polyamide 12 flexible | 63 | 63 |

| Polyamide 12 glass filled | 58 | 75 |

| Polyamide 12 rigid | 68 | 72 |

| PBT – Polybutylene Terephthalate | 90 | 95 |

| PC – Polycarbonate | 90 | 95 |

| PCTFE – Polymonochlorotrifluoroethylene | 75 | 85 |

| PE – Polyethylene | 70 | 80 |

| PEEK – Polyetheretherketone | 85 | 95 |

| PEI – Polyetherimide | 95 | 99 |

| PET – Polyethylene Terephthalate | 85 | 95 |

| Polypropylene Copolymer | 70 | 80 |

| Polypropylene – Homopolymer | 70 | 83 |

| Polystyrene crystal | 85 | 90 |

| Polystyrene – High heat | 90 | 95 |

| PTFE – Polytetrafluoroethylene | 50 | 65 |

| PVDF – Polyvinylidene Fluoride | 65 | 82 |

| SAN – Styrene Acrylonitrile | 75 | 95 |

| Thermoplastic Starch | 52.4 | 53.6 |

| XLPE – Crosslinked Polyethylene | 30 | 80 |

General Rockwell D Hardness Values

| Material | Minimum Value | Maximum Value |

| ABS – Flame Retardent | 20 | 70 |

| ABS – High Heat | 20 | 50 |

| ABS – High Impact | 10 | 30 |

| Acrylic | 70 | 105 |

| Acetal | 75 | 94 |

| CA – Cellulose Acetate | 1 | 80 |

| CAB – Cellulose Acetate Butyrate | 1 | 70 |

| ETFE – Ethylene Tetrafluoroethylene | 1 | 10 |

| EVA – Ethylene Vinyl Acetate | 1 | 1 |

| HDPE – High-Density Polyethylene | 1 | 1 |

| HIPS – High Impact Polystyrene | 1 | 1 |

| LDPE – Low-Density Polyethylene | 1 | 1 |

| LLDPE – Linear Low-Density Polyethylene | 1 | 1 |

| Polyamide 11 30% Glass fiber reinforced | 116 | 116 |

| Polyamide 11 – Rigid | 1 | 25 |

| Polyamide 12 Glass Filled | 107 | 107 |

| Polyamide 6 | 30 | 80 |

| PBT – Polybutylene Terephthalate | 70 | 90 |

| Polycarbonate | 70 | 95 |

| PCTFE – Polymonochlorotrifluoroethylene | 10 | 40 |

| Polyethylene | 1 | 20 |

| PEEK – Polyetheretherketone | 55 | 100 |

| PET – Polyethylene Terephthalate | 50 | 100 |

| Polypropylene – Copolymer | 1 | 20 |

| Polypropylene – Homopolymer | 1 | 30 |

| Polystyrene crystal | 60 | 75 |

| Polystyrene – High heat | 75 | 85 |

| PTFE – Polytetrafluoroethylene | 1 | 1 |

| SAN – Styrene Acrylonitrile | 80 | 100 |

| XLPE – Crosslinked Polyethylene | 1 | 20 |

Which Hardness Scale is Best For You?

That question doesn’t have a definitive answer; however, there is a direction I can suggest you go when choosing what method and what scale is best for your industry and product.

The best way to examine hardness would be to consult your industry experts and literature references for the relevant vertical or region.

I recommend looking at the photo below with ideas about the order of magnitude; however, I don’t recommend any conversion between the scales.

Source - omnexus.specialchem.com

FAQs

Below are the frequently asked questions with decisive answers on the hardness of polymers and polypropylene hardness.

What is the hardness of polypropylene?

The hardness of PP is measured on the Rockwell R scale as 92. It comes at the high end of the softer materials, making it semi-rigid.

How do you increase the hardness of plastic?

The most frequently used method to increase the hardness of plastic is to compound a layer of high-hardness resin on the surface of low-hardness plastic components.

The method best suits extrusion products like sheets, films, pipes, and plates. The most common layering resins are ABS, PMMA, PS, etc.

What is the unit of hardness?

The SI unit for hardness is N/mm².

Which device is used to measure Shore hardness?

Shore Hardness is measured using a device called a Durometer.

Why is hardness in plastics so important?

Hardness is one of the basic properties of plastics.

It enables it to withstand plastic deformation, penetration, scratching, and indentation; hence, hardness is significant for determining specific material applications, pros, and cons from an engineering standpoint.

What is the difference between Shore A and Shore D?

Hardness is one of the basic properties of plastics.

It enables it to withstand plastic deformation, penetration, scratching, and indentation; hence, hardness is significant for determining specific material applications, pros, and cons from an engineering standpoint.

The Takeaway

The hardness of plastic materials is an essential factor to consider when selecting materials for various applications.

The hardness of plastic is influenced by several factors, including its chemical composition, processing conditions, and post-processing treatments.

Understanding these factors can help engineers and designers choose the suitable plastic for their applications.

That was my insight into plastic hardness and its importance.

Always go for a reliable hardness test depending on your material, which will help make good products and save time and money.

I hope you like my piece. Kindly share your thoughts and reviews in the comment box.

Have a wonderful day.

Quick Navigation