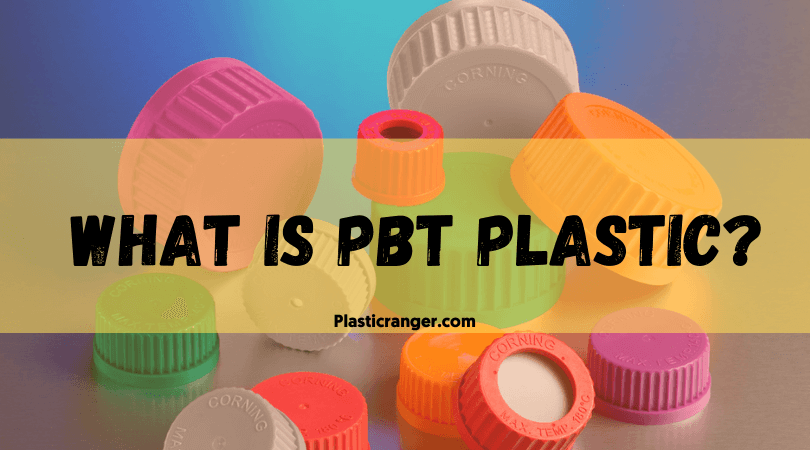

Get ready to discover the exceptional plastic material that defies the odds! Semi-crystalline plastic and injection molding don’t typically mix, but polybutylene terephthalate (PBT) bucks that trend.

Join us as we dive deep into the fascinating world of this versatile and sought-after material.

What is PBT Plastic? (Polybutylene Terephthalate)

Polybutylene terephthalate is a strong, semi-crystalline engineering thermoplastic material created by butanediol and terephthalic acid polymerization.

It belongs to the polyester family of polymers and has characteristics similar to PET(polyethylene terephthalate). The major highlight is the number of methylene units present in a repeating form.

PBT (220 to 225°C) possesses a lower melting point than PET( 250 to 255°C).

The smooth flow of molten material and quick crystallization upon cooling make it highly compatible with injection molding for producing solid components.

Polybutylene Terephthalate is quite popular among mainstream plastic manufacturers thanks to its wide array of applications in automobiles, healthcare, electronics, etc.

Here’s the list of top PBT suppliers:

| Supplier | Brand |

| BlueStar | BlueStar PBT |

| BASF | Ultradur® |

| Lanxess | Pocan® |

| SABIC |

LNP™ LUBRICOMP™

|

| Polyram | RAMSTER® |

PBT products exhibit a wide array of grades highly compatible with Injection molding. These include:

- Filled

- Impact modified

- Reinforced

- Flame retardant

The unfilled PBT grades have a wide range of thickness that helps them provide processing support in injection molding and extrusion techniques.

Flame retardant PBT plastic is also available in the market, and not just that, lubricated Polybutylene Terephthalate versions are also available in both unreinforced and reinforced grades.

Properties of PBT

- It has high material handling capabilities, reducing material costs by a good margin.

- It is stress-resistant and has excellent machining and processing ability.

- It possesses nine short-term mechanical properties, high strength, toughness, and stiffness.

- It has impressive creep resistance, moisture absorption, and excellent dimensional stability.

- Polybutylene Terephthalate helps in protecting electrical components with high electric resistance.

- Appropriate flame-resistant grades are also available in specific cases.

- Good UV blocking coupled with good heat aging behavior

- PBT material has high heat deflection temperatures and a high-temperature index, which helps resist short-term thermal excursion and longer-term heat exposure.

- Decent durability in harsh chemical environments, especially in automobile underhood applications.

- Excellent chemical resistance against chemicals like alcohols, aromatic hydrocarbons, ketones, diluted acids, oils, solvents, and greases. That makes it highly suitable for producing plastic parts in constant contact with oils and gasoline.

Here are the general properties of PBT material:

| Chemical Resistance | |

| Alcohols | Good |

| Aromatic hydrocarbons | Good |

| Greases and Oils | Good |

| Alkalis | Average |

| Ketones | Good |

| Electrical properties | |

| Dielectric strength ( kV.mm-1 ) | 20 |

| Dielectric constant @ 1 kHz | 3.2 |

| Dissipation factor @ 1 kHz | 0.002 |

| Volume resistivity ( Ohm.cm ) | 10 raise 15 |

| Thermal Properties | |

| Heat-deflection temperature – 1.8 MPa ( °C ) | 60 |

| Heat-deflection temperature – 0.45 MPa ( °C ) | 150 |

| Upper working temperature ( °C ) | 120-? |

| Physical Properties | |

| Density ( g.cm-3 ) | 1.31 |

| Limiting oxygen index ( % ) | 25 |

| Water absorption – over 24 hours ( % ) | 0.1 |

Limitations of PBT

- Strength and rigidness are lower than PET

- Glass resistance temperature is also lower than PET.

- Poor resistance to hydrolysis

- Warping is evident because of constant differential shrinkage.

- High mold shrinkage

Polybutylene Terephthalate Alloys And Its Blends

Polybutylene Terephthalate alloys have various blends in highly demanding conditions for particular purposes.

The blend is formed chiefly with PC and PET materials, giving various advantages for specific engineering applications.

It highlights the strengths and overshadows the limitations, achieving top-notch results in high-end and complex applications.

Here are specific benefits:

- Delivering robust engineering properties in a malleable, chemically resistant material. It gives designers the freedom and ability to give full results without trading off mechanical performance.

- The malleability remains consistent till 40 °C yet retains most of its stiffness in the hot car interior. Moreover, specialty-graded variations can resist the complex performance need of safety equipment like doors and containers.

- They combine multiple features to achieve a specific task. Malleability, chemical resistance, die-electric strength, and electrical resistance to oils, greases, and gasoline match the heat shock criteria.

- Variants with weatherable grades are functional in outdoor electrical applications.

Polycarbonate/Polybutylene Terephthalate (PC/PBT) Blend

Polycarbonate and PBT materials have many similarities, but the significant similarities are tensile strength and flexibility.

Both materials complement each other. In the PC and PBT blend:

- Polycarbonate helps in balancing resistance capabilities with impact, stiffness, and heat. On the other hand

- Polybutylene Terephthalate helps maintain chemical resistance

- PC blends show higher module support compared to standalone PC

- Adding a minimal amount of polyester can help in improving the PC’s flexibility

- Other PC/Polyester blends have better mixing abilities compared to PC/PBT blends

Let’s have a look at the strengths and the drawbacks of the blend:

| Strength | Drawbacks |

| Impressive heat resistance – up to 140°C |

Not compatible with thin wall design because f its medium flow properties

|

| Fantastic weatherability | High Shrinkage |

| Good UV resistance | Opaque |

| Good color retention |

Shows weakness towards esters, ketones, alkalis, and halogenated hydrocarbons

|

|

Excellent toughness – upto -40°C

| – |

Facinating Read – What is Bakelite?: The Plastic That Changed the World

Applications of PBT Plastic

PBT offers applications in various industries thanks to its versatile nature and excellent physical properties. The vast range of valuable properties gives both designers and processors tremendous advantages.

- Automobile

- Industrial Applications

- Electronics and Electrical

- Consumer Goods

Automobile

PBT’s supreme mechanical and electrical properties, suited wonderfully by decent thermal stability and excellent chemical resistance, make it more than qualified enough to manufacture various automobile parts for cars and trucks.

Good resistance to extreme environmental resistance also makes PBT suitable for automobile underhood applications.

- Applications for both automobile interior and exterior include:

- Handles and Fans

- Cowl vents

- Fuel system components

- Windsheid wiper covers

- Mirror Housings

- Fuse boxes

- Connecters

- Sensor Housings

- Ignition system components

Electronic and Eletrcical

Leakage and breakdown in power circuitry are huge problems. PBT materials with high electrical resistance and dielectric strength become a guard for electrical and electronic components.

Many parts are specifically made for electrical and electronic components to be used for their power and signal purposes. There are products like:

- Power sockets made for modular building panels

- Connectors, sensor housings, chip sockets

- Transformer insulation

- Terminal Boards

- Cable Liners

- Fiber optic buffer tubes

- Switches and Circuit breakers

Industrial Applications

Fabulous mechanical properties associated with PBT help maintain a subtle image for industrial applications. Short-term mechanical properties like good smack impact, high stiffness, and high strength make Polybutylene Terephthalate well-versed for tough and rigid industrial applications.

Typical applications include street lamp reflectors, pump housings, fluorescent lamp bases, monofilaments, filter media, and packaging components. Mixing alloys with PBT can improve the scope of industrial applications by a large margin.

PBT alloys can produce small off-rode file tanks, tractor hoods, panels, power tool housings, and conveyor chain components with the added dimension of more excellent toughness.

Consumer Goods

Consumer products have specific conditions for smooth applications. Conditions like high durability, high-temperature resistance, and electrical stresses are necessary for any material.

The most common industrial applications include oven door handles, motor brackets, housings, closure panels, home, and office furniture, etc.

PBT blend with polyester allows strength and rigidness in such parts, likely rough contacts like closure and kick panels, lids, covers, seatbacks, and bottoms.

Processing of PBT

All the PBT grades and variations are mainly processed in injection molding at 230° to 270° C.

However, it can also be processed in extrusion and blow molding for specific applications. In addition, unreinforced PBT plastic is also used in fiber spinning processes for particular applications.

| Cooling Temperature |

250-275°F – 2-4 hours

|

| Maximum continuous service temperature | 80-140°C |

| Minimum continuous service temperature | -40°C |

| L/D Screw ratio | 20:1 |

| HDT – 0.46MPa | 115 to 150°C |

| HDT – 1.8 MPa | 50-85°C |

| Brittle transition temperature | -40°C |

| Compression ratio | 2.5-3.0 |

Conditions

- There are certain conditions during and before processing that is must obey:

- Before processing injection molding, pre-dying is extremely important to control moisture content – 0.02%

- Mold shrinkage – The higher the model temperature, the higher the shrinkage – Unfilled: 1.4-2.0%, Glass-fiber Reinforced: 0.4-0.6%

- Injection pressure – 100-140 MPa.

- A graded three-zone screw needs to be used.

The Future of PBT Material

PBT is an engineering thermoplastic that has seen significant growth in demand in recent years. Before the pandemic, PBT’s compound annual growth rate (CAGR) was forecasted to be 5%.

Despite the challenges faced in the last few years, the demand for PBT has remained buoyant in critical industries like automobiles and electronics.

Engineers strive to produce lightweight yet durable vehicles as the automobile industry evolves rapidly.

This has increased demand for PBT, which can replace traditional metals like bronze, stainless steel, and iron in various interior and exterior automobile applications.

PBT’s properties make it an attractive choice for manufacturers as it offers excellent mechanical and electrical properties, making it durable, heat resistant, and chemically resistant.

However, PBT faces competition from other engineering plastics, with polycarbonate (PC) being the most significant rival. PBT and PC share similar properties, making PC a viable alternative to PBT in some applications.

Bio-based PBT is developing and may offer a long-term eco-friendly alternative to traditional PBT.

Regarding regional consumption, the Asia-Pacific market leads the pack regarding PBT demand in the manufacturing sector.

Countries like China, Vietnam, India, and Bangladesh have seen a massive surge in their manufacturing industries, highlighting the potential for engineering plastics like PBT in the region.

While the growth forecast for PBT remains strong, it’s essential to consider the environmental impact of PBT production and disposal.

As we continue to advance technology and research, we must explore more sustainable alternatives to meet the functional requirements of PBT while minimizing its adverse environmental impact.

Interesting Read – Compression Molding Process – A Detailed Guide

FAQs

Below are the frequently asked questions on PBT polymer. Let’s dig deep to know more.

Is PBT biodegradable?

PBT’s biocompatibility and biodegradability are often compared to PLA and PCL, as these polymers are heavily used in 3D printing. The lack of research on the material is why much can’t be said about its biodegradable properties and attributes.

What is the critical difference between PET and PBT?

Both PET and PBT are thermoplastic solid polymers. However, discussing the differences, PBT has slightly lower strength and rigidity, lower glass transition temperature, and moderately better impact resistance. However, a significant similarity between both is that both are sensitive to hot water after above 60°C.

How do you make PBT?

PBT creation process is quite similar to thermoplastics. However, it is produced using polycondensation of dimethyl terephthalate with 1,4–butanediol using special catalysts.

Is PBT better than abs?

On paper, PBT is better than ABS in smack resistance, durability, color stability, and maintaining physical presence shine for a longer period. ABS is cheap but less durable, whereas PBT is more expensive.

What are PBT keycaps?

PBT is one of the most sought-after plastic materials for making keycaps. They hold up well with time and are also used in gaming setups. PBT is probably the most durable material used for manufacturing keycaps.

The Takeaway

Let’s wrap up our exploration of PBT plastic – a powerhouse material with excellent mechanical and electrical properties. From its heat and chemical resistance to its durability, it’s no wonder PBT is a popular choice in many industries.

But let’s not forget the potential environmental impacts of its production and disposal.

It’s crucial to consider sustainable alternatives as we move forward. We’re excited to see what innovations and breakthroughs in materials science will bring us more eco-friendly options that rival PBT plastic’s capabilities.

Thank you for taking the time to read my work! I’m eager to hear your thoughts and insights on the topic. Let’s start a conversation in the comments section and share our perspectives.

Quick Navigation

Providing good knowledge about Engineering Plastic. It is very helpful for manufacturing units involved in Electrical & Electronics parts.

Property explanation of PPT and PC is helpful for manufacturing of Electrical & Electronic components. It is also helpful a good feedback to decide purchase of Injection Molding Machine.

Thanks a lot