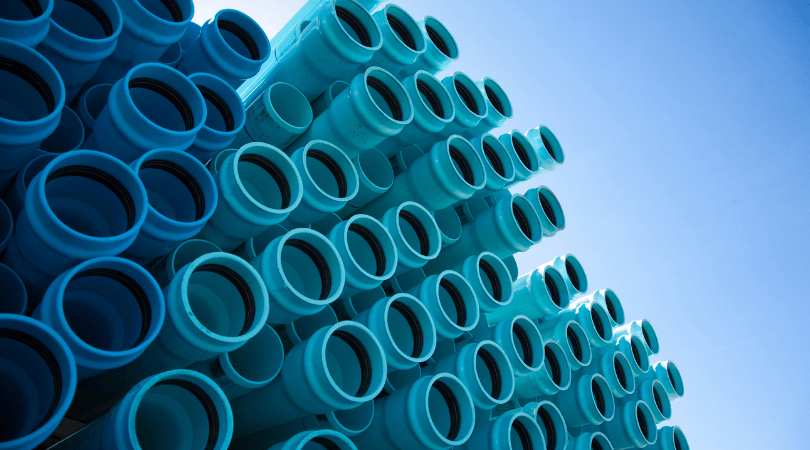

PVC pipes are widely used for various applications, including water mains, irrigation, and sewage pipes. They have many beneficial properties: long-lasting, easy to install, strong, durable, lightweight, cost-efficient, and sustainable. However, it is important to know their sizes and dimensions when selecting a PVC pipe for a specific use.

What are PVC Pipe Sizes and PVC Pipe Dimensions?

Pipes made from PVC plastic are measured in a nominal system. Meaning that all the measurements are based on the types of structures rather than specific measurements.

For example, 0.84 measured from one pipe’s end to another is categorized as a one-inch pipe.

PVC Pipes vary in size and are classified into three types – schedule 40, schedule 80, and schedule 120.

To avoid cost overruns, misuse, plumbing malfunctions, and project delays, it’s essential and helpful for you to do thorough research and find the right product fit.

How Is PVC Pipe Measured?

A size measurement table for Schedule 40 and Schedule 80 PVC pipes.

| Measurement |

Outer Diameter (OD)

|

| Diameter |

PVC Pipe Size Translation

|

| 0.84” | ½” |

| 1.05” | ¾” |

| 1.315” | 1” |

| 1.66” | 1 ¼” |

| 1.9” | 1 ½” |

| 2.375” | 2” |

| 3.5” | 3” |

| 4” | 3 ½” |

| 4.5” | 4” |

| 5.563” | 5” |

| 6.625” | 6” |

| 8.625” | 8” |

| 10.75” | 10” |

Interesting Read – HDPE Pipe Sizes and Dimensions | A Complete Analysis

Pipe measurements are calculated on a nominal scale. Meaning that measurements are characterized by structures at hand rather than actual scale measurements.

I have shared a step-by-step explanation to help you select the correct size of pipes you need.

- Keep the pipe on a hard surface with one end facing you

- Take a tape or ruler to measure your pipe’s right outer edge to its left outer edge. Maintain your ruler straight and level to get an accurate measurement.

- Now compare “your measurement” with the “Average OD” in the above chart.

- Choose the pipes based on the Average OD your measurement was paired with.

Take note; these measurements are concerned with the outer edge of the pipe, not the inner. Therefore, your outer edge may change depending on your required pipe schedule.

Schedule 40 PVC Pipe Dimensions and More

| Nominal Pipe Size (Inches) | Outside Diameter (OD) | Min. Wall Thickness | Inside Diameter (ID) |

Linear Weight Density (Wt. / Ft.)

|

| 1/8 | 0.405 | 0.068 | 0.249 | 0.051 |

| 1/4 | 0.54 | 0.086 | 0.344 | 0.086 |

| 3/8 | 0.675 | 0.091 | 0.473 | 0.115 |

| 1/2 | 0.84 | 0.109 | 0.602 | 0.17 |

| 3/4 | 1.05 | 0.113 | 0.804 | 0.226 |

| 1 | 1.315 | 0.133 | 1.029 | 0.333 |

| 1 1/4 | 1.66 | 0.14 | 1.36 | 0.45 |

| 1 1/2 | 1.9 | 0.145 | 1.59 | 0.537 |

| 2 | 2.375 | 0.154 | 2.047 | 0.72 |

| 2 1/2 | 2.875 | 0.203 | 2.445 | 1.136 |

| 3 | 3.5 | 0.216 | 3.042 | 1.488 |

| 3 1/2 | 4 | 0.226 | 3.521 | 1.789 |

| 4 | 4.5 | 0.237 | 3.998 | 2.118 |

| 5 | 5.563 | 0.258 | 5.016 | 2.874 |

| 6 | 6.625 | 0.28 | 6.031 | 3.733 |

| 8 | 8.625 | 0.322 | 7.942 | 5.619 |

| 10 | 10.75 | 0.365 | 9.976 | 7.966 |

| 12 | 12.75 | 0.406 | 11.889 | 10.534 |

| 14 | 14 | 0.437 | 13.073 | 12.462 |

| 16 | 16 | 0.5 | 14.94 | 16.286 |

| 18 | 18 | 0.562 | 16.809 | 20.587 |

| 20 | 20 | 0.593 | 18.743 | 24.183 |

| 24 | 24 | 0.687 | 22.544 | 33.652 |

Schedule 40 pipes are generally white or silver but can be found in different colors.

The specialty of these pipes is that they are thinner than the 80s and 120s, making the liquid pass through faster than other pipes.

These pipes can also withstand tremendous pressure; as far as the heat resistance capacity is concerned, all three schedules can resist up to 140 degrees.

The most common application of Schedule 40 PVC pipes can be found as drainage around buildings, golf course construction, potable water lines, pools, spas, and gas lines.

The pressure-withstanding capacity of those pipes is 120 to 810 pounds per second inch (PSI).

Fascinating Read – PVDF Pipe Sizes and Dimensions | The Complete Guide

Schedule 80 PVC Pipe Dimensions and More

| Nominal Pipe Size (Inches) | Outside Diameter (OD) | Min. Wall Thickness | Inside Diameter (ID) |

Linear Weight Density (Wt. / Ft.)

|

| 1/8 | 0.405 | 0.095 | 0.195 | 0.068 |

| 1/4 | 0.54 | 0.119 | 0.288 | 0.11 |

| 3/8 | 0.675 | 0.126 | 0.407 | 0.152 |

| 1/2 | 0.84 | 0.147 | 0.546 | 0.225 |

| 3/4 | 1.05 | 0.154 | 0.742 | 0.306 |

| 1 | 1.315 | 0.179 | 0.956 | 0.45 |

| 1 1/4 | 1.66 | 1.191 | 1.278 | 0.621 |

| 1 1/2 | 1.9 | 0.2 | 1.5 | 0.754 |

| 2 | 2.375 | 0.217 | 1.939 | 1.043 |

| 2 1/2 | 2.875 | 0.276 | 2.29 | 1.594 |

| 3 | 3.5 | 0.3 | 2.863 | 2.132 |

| 4 | 4.5 | 0.337 | 3.786 | 3.116 |

| 6 | 6.624 | 0.432 | 5.708 | 5.951 |

| 8 | 8.625 | 0.5 | 7.565 | 9.04 |

| 10 | 10.75 | 0.593 | 9.492 | 13.413 |

| 12 | 12.75 | 0.687 | 11.294 | 18.44 |

| 14 | 14 | 0.75 | 12.41 | 22.119 |

| 16 | 16 | 0.843 | 14.212 | 28.424 |

| 18 | 18 | 0.937 | 16.014 | 36.487 |

| 20 | 20 | 1.031 | 17.814 | 44.648 |

| 24 | 24 | 1.218 | 21.418 | 36.341 |

Schedule 80 pipes are thicker than the 40s but still not the thickest. It is manufactured to be stronger and thicker than the Schedule 40 pipes and possesses a higher pressure withstanding capacity of 210 to 1230 PSI.

These pipes are generally dark grey but may vary.

The most common applications are industrial plating, chemical processing, wastewater treatment management, and deionized water lines.

Schedule 120 PVC Pipe Dimensions and More

| Nominal Pipe Size (Inches) | Outside Diameter (OD) | Min. Wall Thickness | Inside Diameter (ID) | Linear Weight Density (Wt. / Ft.) |

| 1/2 | 0.84 | 0.17 | 0.48 | 0.236 |

| 3/4 | 1.05 | 0.17 | 0.69 | 0.311 |

| 1 | 1.32 | 0.2 | 0.891 | 0.464 |

| 1 1/4 | 1.66 | 0.215 | 1.204 | 0.649 |

| 1 1/2 | 1.9 | 0.225 | 1.423 | 0.787 |

| 2 | 2.38 | 0.25 | 1.84 | 1.111 |

| 2 1/2 | 2.88 | 0.3 | 2.239 | 1.615 |

| 3 | 3.5 | 0.35 | 2.758 | 2.306 |

| 4 | 4.5 | 0.43 | 3.574 | 19 |

| 6 | 6.625 | 0.532 | 5.434 | 36.39 |

| 8 | 8.625 | 0.719 | 7.189 | 60.44 |

| 10 | 10.75 | 0.844 | – | 98.29 |

| 12 | 12.75 | 1 | – | 125.49 |

| 14 | 14 | 1.094 | – | 150.79 |

| 16 | 16 | 1.219 | – | 192.43 |

| 18 | 18 | 1.375 | – | 244.14 |

| 20 | 20 | 1.5 | – | 296.37 |

| 22 | 22 | 1.625 | – | 353.61 |

| 24 | 24 | 1.812 | – | 429.39 |

Engaging Read – ABS Pipe Sizes & Dimensions For Schedule 40 and 80

Schedule 120 pipes are the strongest and thickest in the market and are suitable for use in the Automotive and Construction industry.

Schedule 120 pipe thickness and durability help slow down mild to high-pressure systems with an impressive withstanding capacity of 380 to 1,010 PSI.

Take note; a thicker pipe doesn’t mean it will provide maximum security. It all boils down to the solution you are transporting and your chosen flow rate; mishaps are bound to happen if you choose the wrong size and fit.

For example, if you use a heavy pipe for general solution purposes, your flow rate can slow down significantly.

Depending on the construction site you’re working in, always first try to contact the local government office for building code regulations.

It is vital to use pipe schedules that meet not just your requirements but also the local requirements.

Once you figure out the pipe sizes, ordering pipe valves is next.

A great way to keep the pipe flow in control is to figure out which size of valves you need. When you are ready to install pipes and valves, do extensive research about them to avoid mishaps.

What is Wall Thickness, and Why is it Important?

As the PVC pipe’s thickness increases in diameter, the walls must also be thicker. If the walls were too thin, the pipe would lack structural durability.

We’ve already established that it is not easy to figure out PVC pipe ID sizes, and you cannot add a specific size on the label; it is way trickier than that.

As we’ve seen in the table, the OD for 1/2″ PVC pipe is 0.840,” and the OD for 3″ PVC pipe is 3.500.”

If the nominal size is the ID, 1/2″ PVC pipe walls are .170″ thick, and 3″ PVC pipe walls are 0.250″ thick. Thus, the wall thickness of the pipe continues to increase as the pipe gets bigger.

Keep in mind that all the data shared in the above tables came from reliable sources and are trustworthy. However, they are only for general information purposes. We’re not recommending anything to be used directly. Refer to manufacturer instructions and the technical product manual for current and accurate information.

FAQs

Below are the frequently asked questions on PVC pipes sizes. Let’s dig deep to know more.

Is PVC piping better than copper?

Contrary to copper pipes, PVC pipes can resist corrosion as they are plastic and thicker than copper pipe; they can also withstand a good amount of pressure and impact. In addition, PVC pipes are better placed in high-traffic areas as it’s not a good heat conductor like copper.

How much weight can PVC pipe hold?

Most PVC pipes can hold at least 28 pounds of weight before they start bending. However, sometimes longer PVC pipes begin to bend under their weight. A prime rule of thumb is never to use PVC pipes to hold larger quantities of weight, especially if you don’t want them to become stiff.

What is the lifespan of any PVC pipe?

The lifespan of a general PVC pipe is about 50 to 80 years.

Which is the largest PVC manufacturing company in the world?

Shintech, based in Houston, Texas, United States, is the target PVC manufacturer in the world.

Which is the largest PVC pipe manufacturing company in the world?

JM Eagle Inc. (JM Eagle) is the world’s largest plastic pipe manufacturer headquartered in Los Angeles, United States.

What is the difference between PVC and HDPE pipes?

Although perceived to be too similar, PVC and HDPE pipes have a fair share of differences to make them distinguishable. PVC is a durable vinyl polymer, whereas HDPE is a polyethylene thermoplastic made from petroleum. Both pipes are used extensively worldwide and are almost comparable with properties applications barring some subtle differences. When examining extreme situations like rain, wind, stress, heat, and cold, HDPE is more resilient.

Suggested Read

- What is Polyethylene? | How is Polyethylene Made | Types of Polyethylene | Processing of PE

- Thermal Properties of Plastics | The Ultimate Guide

- Which is the Best ABS Glue? | The Definitive Guide on Bonding ABS Properly

- What is PLA Plastic (Polylactide)? | A Simple and Definitive Guide

- How is Plastic made? A Simple and Detailed Explanation.

- What is Bakelite?: The Plastic That Changed the World

Final Thoughts

That was all I had to say about PVC sizes and PVC Dimensions. Refer to the chart for appropriate information depending on your application. However, consulting the supplier is the best option for accurately procuring the best products. That will save you significant time, money, effort, and exceptional production results, bringing much-needed customer satisfaction to your business.

Kindly share your reviews in the comment box and share this article to make people know how insightful you are.

Quick Navigation

nice info

thanks