The physical properties of any material or polymer are essential in determining its applicability and features. Let’s discuss the physical properties of all the mainstream plastic materials. Without further due, here we go.

What are the Physical Properties of Plastic Materials?

Specific Gravity: 73°F, Water Absorption: Immersion 24 hours

| Physical Properties | ||

| Materials | Water Absorption | Specific Gravity |

| ABS | 0.3 | 1.04 |

| Acetal | 0.25 | 1.42 |

| Acrylic | 0.2 | 1.19 |

| CAB – cellulose acetate butyrate | 1.4 | 1.2 |

| CE – Canvas Phenolic | – | 1.37 |

| Polyamide | 0.24 | 1.43 |

| ECTFE – Ethylene Chlorotrifluoroethylene | <0.10 | 1.68 |

| HDPE | 0.1 | 0.96 |

| Nylon | 1.2 | 1.14 |

| PBT | 0.08 | 1.3 |

| PEEK | 0.5 | 1.32 |

| PET | 0.1 | 0.38 |

| PETG | 0.2 | 1.27 |

| Polycarbonate | 0.15 | 1.2 |

| Polypropylene | – | 0.91 |

| PTFE | 2.15 | <0.01 |

| PVC | 0.06 | 1.42 |

| PVDF | 0.02 | 1.78 |

| TPE | – | 0.95 |

| UHMW | – | 0.93 |

Physical Properties Of Plastic Materials

- These materials are both lightweight and chemically stable.

- They can be easily molded into various shapes and sizes.

- They are effective at insulating and have a low tendency to conduct heat.

- They have good impact resistance and do not rust easily.

- They have good transparency and are resistant to wear.

- They have poor dimensional stability and are prone to deformation.

- They have a low cost of processing

The Importance of Physical Properties

Good physical properties can make or break things for the integrity of a product. Specific gravity and water absorption are integral to a product’s quality.

Water Absorption

Talking about water absorption abilities, a material that properly becomes very useful for manufacturers, increasing its potential applications significantly.

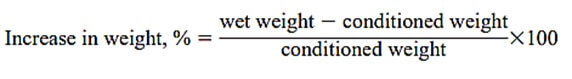

Water absorption is the ability of plastic material to absorb water or moisture from the atmosphere. Absorbed water acts as a plasticizer, reducing the strength and glass transition temperature of the plastic. It can be reversed, but absorbed moisture can also trigger unalterable degradation of polymer structure.

Factors affecting water Absorption

- Type of plastic

- The proportion of additives, filaments, fillers, and reinforcements used

- Morphology

- Length of exposure

- Relative humidity of temperature

- Composites – fiber fraction and orientation

Below I have shared the water absorption values:

| Water Absorbtion Values | ||

| Materials | Max Value (% weight) |

Min value (% weight)

|

| ABS | 0.8 | 0.1 |

| CAB | 2.2 | 1.9 |

| ETFE | 0.03 | 0.03 |

| HDPE | 0.01 | 0.005 |

| LDPE | 0.015 | 0.005 |

| Nylon | 1.9 | 1.6 |

| PBT | 0.2 | 0.1 |

| PC | 0.2 | 0.1 |

| PE | 0.06 | 0.02 |

| PEEK | 0.5 | 0.1 |

| PET | 0.2 | 0.1 |

| PETG | 0.1 | 0.1 |

| PP (Both homopolymer and copolymer) | 0.1 | 0.01 |

| PVDF | 0.05 | 0.03 |

| PVC | 0.4 | 0.04 |

Interesting Read – Thermal Properties of Plastics | The Ultimate Guide

Surface Quality

Polymers usually have a “Benchmark” Density that can provide a value of the surface gravity of a particular material.

However, several factors can affect surface gravity, such as the absorption of solvent and crystallinity.

The density can differ within portions of the same sample, such as thermal history, porosity, crystallinity, and changes in material composition.

The surface gravity of a material can be determined using two main methods.

Method A is used for testing solid plastic in water, and the method is used in any other liquid other than water.

Method A is more common than the other and can be implemented with a rod, sheet, tube, and molded chunks of plastic materials not contrived by water. The same is weighted in air, first and then in distilled water at 23°C.

Now the following formulas will be used to determine the surface gravity.

Specific Gravity = (Weight A / Weight B)

Density = (Weight A / Weight B) * 0.9976 g/cm3 , where 0.9976 g/cm3 is equal to the density of distilled water at 23°C

Density and surface gravity determination is crucial for the custom plastic sheet industry as the plastic sheets are sold on a cost-per-pound basis. The lower the surface area of a specific material, the more material you will get on a per-pound basis.

Let me give you an example to understand that better; Polypropylene and PET have different densities and surface gravity.

PP has a surface density of 0.90 and PET – of 1.40. When comparing materials, accounting size, and constant gauge, customers can witness a 30% reduction in density from PET to PP and an increased yield on pounds purchased.

All the information and values written above are for information purposes only. To know the perfect value consulting the material supplier would be the best option.

Engaging Read – Melting Point of Plastics | The Ultimate Guide

FAQs

Below are the frequently asked questions on plastic properties in physical nature. Let’s dig deep to know more.

Can water pass through plastic?

The amount of moisture absorbed by plastic is limited. The moisture absorption density can be attributed to ambient conditions such as temperature, humidity, contact time, etc. Nylon, aka polyamide exhibit the highest water/moisture absorption.

What are the common properties of plastic?

Some common properties are Chemical resistance, corrosion resistance, ductility/malleability, fracture toughness, hardness, plasticity, density, thermal conductivity, formability, impact resistance, etc.

What properties make using plastic material a smart choice?

Plastics are resistant to many atrocities like corrosion, and chemical attacks, have a high strength-to-weight ratio, thermal conductivity, good durability, excellent shock resistance, low cost, easily available in both low and high quantities, etc. That bouquet of beneficial properties makes using plastic material for manufacturing purposes a very smart choice.

What are the two types of plastics?

There are two main types of plastics – Thermoplastics and thermosets.

What is the toughest plastic?

In terms of durability, strength, and impact resistance, Polycarbonate is the toughest plastic material out there. It is 200 times stronger than glass and is often used for making bulletproof windows for homes, offices, and even automobiles.

Suggested Read

- Mechanical Properties of Plastic Materials | The Definitive Guide

- What is Compressive Strength of Plastics | The Complete Guide

- What is the Density of Plastics? | The Complete Guide

- What are Modulus of Elasticity Units | The Ultimate Guide

- What is Processing and Drying Temperatures of Plastics

- Dielectric Strength of Plastics | Electrical Properties of Plastics | The Definitive Guide

- What is Shore Hardness Scale? | The Complete Guide

The Takeaway

Plastics showcase a myriad of physical properties, including lightweight nature, durability, and insulation capacity.

Their highly malleable nature allows for diverse manufacturing opportunities, from rigid structures to flexible films. However, their non-biodegradable nature poses significant environmental challenges. Despite their convenience and ubiquity, promoting plastic waste management and seeking sustainable alternatives for preserving our ecological balance is essential.

I trust you enjoyed my work. Please feel free to share your thoughts and feedback in the comment section.

May your day be filled with joy.

Quick Navigation

How plastic angles compare with Steel angles for their tensile, compressive, shear strength, etc., to be used on TL Towers. Further, Bolts for making joints of various members shall be plastic or steel coated with plastic without causing any corrosion of steel.