Hello people, I hope you’re doing well. Today I’m going to share a detailed, easy to follow guide on the best acrylic glue and what is the best way to use it. So without further ado, let’s begin.

Which is the Best Plexiglass Glue

Superglue and Epoxy glue are the two best plexiglass glues out there. They bond very easily, are easy to apply, and have a number of applications.

Gluing plastics can be a real challenge, especially if you don’t know which glue suits which plastic. Today I’m sharing a fantastic guide on gluing plexiglass or acrylic. However, finding the best sticking glue for any plastic can be unsettling, as plastic doesn’t stick to the adhesives that quickly.

In addition, plastic’s lack of roughness, porosity, and smooth surface makes it difficult to bond with traditional adhesives.

Let’s find out which is the best glue for acrylic plastic.

The Best Plexiglass Glue

Even before you begin gluing plexiglass, the first thing you should ensure is that the material at hand is plexiglass or something else. Sometimes similar looking material plexiglass or acrylic is mistakenly taken as plexiglass, which is PVC.

This significantly affects the bonding process, resulting in breakage in the adhesive seam or damage to the material.

After that, you must ensure that you bind Plexiglass with Plexiglass or any other material. For example, the properties you consider while gluing will change drastically if you want to bond it with wood.

The reason is their overall structure; while plexiglass is smooth, wood is porous.

In addition, the adhesive should adapt to the transparent plexiglass and not lead to any clouding of the bonded material.

The following are the adhesives best suited for gluing plexiglass to anything.

| Gluing Plexiglass to… |

Preferable adhesive

|

| Plexiglas |

Acrylic Adhesive, Super Glue, Silicone Rubber, Epoxy Adhesive

|

| Rubber | Superglue |

| Metal |

Superglue, Epoxy Adhesive, Silicone Rubber

|

| Stone |

Silicone Rubber, Superglue, Epoxy Adhesive

|

| Hard Plastics |

Silicone Rubber, Superglue, Acrylic Adhesive, Epoxy Adhesive

|

| Ceramics |

Epoxy Adhesive, Silicone Rubber, Superglue

|

Fascinating Read – Which is the Best ABS Glue? | The Definitive Guide on Bonding ABS Properly

How to Glue Plexiglass with Superglue

Superglue is everywhere, very commonly found in our houses. It cures quickly and bonds with many different materials firmly and permanently.

However, if you use superglue as a plexiglass adhesive, you should remember that it has no gap-bridging properties. Therefore, the part of being bonded must be an exact fit.

Areas of Application

Superglue is typically suitable for selective and small bondings that do not need a long pot life. The glued seam can be put through high weights. It loads once the adhesive is cured.

This is because the Instant is a powerful adhesive that can resist high loads. However, super glue can only be applied to the Plexiglass area, which is not supposed to be visible later.

The cured superglue has a white color that will look unpleasant or unattractive on a transparent Plexiglass pane.

How to Apply?

It is compulsory to clean the gluing area before applying the acrylic glue. Using isopropanol and a soft, lint-free cotton cloth would be the best cleaning option. Then apply the adhesive to one side and join the substrates together.

How to Glue Plexiglass with Epoxy Glue

Epoxy resin adhesives have two main components – a resin and a hardener, which sets off a chemical mixing reaction. The resin hardens, and a solid and irrepressible bond is formed that can also be machined.

Another significant advantage of using Epoxy resin is that it’s effortless to color it. The adhesive is also compatible with mixing various additives and filling materials.

However, one needs to consider the suitability of the adhesives with the additives to be bonded not to diminish the adhesive’s properties.

Epoxy glue is helpful in repairing Plexiglass and can also be utilized as an efficient Plexiglass glue. If you want to bond Plexiglass to wood, then epoxy is the best method.

Here, to format a successful bond and make any mistakes, the most important thing to note is the coefficients of thermal expansion and the stress on the bonded areas. If the bonded joint is flexible and elastic, use a silicone adhesive rather than an epoxy resin.

Areas of Applications

A two-component-based Epoxy resin is an intelligent choice for acrylic and acrylic sheets if you want to bond it with a non-shrinking material.

If you talk to manufacturers, they advise using Epoxy adhesives to resist heavy loads thanks to their qualities like vibration-damping and durability.

However, my experience tells me that acrylic adhesives or acrylic silicone are more capable of being used in shrinking and vibrating workpieces.

How to Apply?

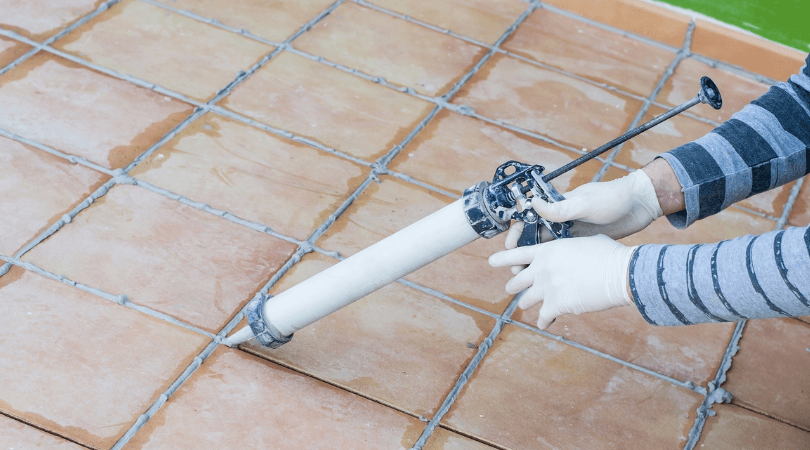

Before the application, the two components of the adhesives must be mixed together. If your products have been supplied in a double-drummer cartridge, it is straightforward – press the cartridge and empty your desired amount in a plane base. Next, measure out an equal amount of each component and mix them in a suitable mixing dish.

Properly mix both components using a wooden scapula/turner until an equivalent mass has been created. You can also use the mixing nozzle, but mixing with it would be enough.

Also, note that the mixing nozzle can only be used once; after that, it will be useless.

The surface of substrates must be cleaned properly, and it should be free of dust particles, grease, oils, and dirt. After the cleaning session involving acetone or isopropanol, the surface will become lightly roughened and must be cleaned again.

The adhesive can then be applied delicately on one side. You should finish the preparation work before mixing the adhesive as you have a concise port life.

The substrates are now glued, and an excellent bond will be formed after some time (usually after 15-20 minutes). The bond will become the strongest after 24 hours. Until then, the substrates should be formed together.

Interesting Read – What is the Best Glue for Plastic Parts | The Ultimate Guide

How to Glue Plexiglass with Acrylic Silicone?

Acrylic silicone is best known as a suitable Plexiglas adhesive. It is applied with thicker beads in a zigzag pattern and heavily decreases the risk of air inclusions, especially when gluing acrylic over a wide area.

The adhesive bonds created are robust, durable, and pressure-proof. In addition, acrylic silicone’s UV, water, and weather resistance properties make it like a cherry on the top of the cake.

Areas of Application?

Acrylic silicone is the definitive choice for bonding laminar plexiglass. It efficiently prevents air inclusions in the substrates as the thickly applied adhesive blends in seamlessly. Thereby, it fills all the gaps. It also acts as a sealant during the bonding process and has a gap-filling effect.

How to Apply?

Acrylic silicone is applied in thick beads. Both substrates should be grease, dirt, dust, and oil clean as usual. Applying the adhesive ensures that the air between the two substrates can escape toward the outer edges when joining. Once the glue is used, you can join the substrates and fix them.

After that, giving the bond a little extra curing time will show the best results.

How to Glue Plexiglass with Acrylic Adhesive?

Acrylic-based adhesives are styrene-free adhesives and should be bought as Methylmethacrylate (MMA) adhesives.

When this adhesive is applied to Plexiglass, the adhesive, and substrates are prone to form a chemical bond with each other as their chemical formulations are very similar.

That results in forming a solid and resilient bond.

However, being cautious in this type of bonding is essential, as stress cracks can appear on the surface after bonding.

But the acrylic adhesive also comes with some surprises.

Arguably, the most significant advantage of this adhesive is that it moves on its own. It impeccably fills the gaps between the substrates and thus establishes a perfect bonding.

Area of Application

Due to its limited pot life, transparent curing, and adhesive seam strength, an acrylic-based Plexiglass adhesive is ideal for bonding over large areas.

The best example to explain this is how you can glue and join a second Plexiglass pane onto a damaged one and repair it if needed.

If the process is done correctly, the acrylic adhesive will glue the two Plexiglass panes solidly together after some time.

How to Apply?

This adhesive (like all the others on the list) also requires thorough cleaning after applying the glue on one side. Now, join the substrates.

Joining the substrates is essential to fix the substrates, especially when bonding plexiglass to one side.

Engaging Read – What is Shore Hardness Scale? | The Complete Guide

Secret Tips on How to Perfectly Use Acrylic Glue (Plexiglass Glue)

Mix Components if required: As said above, two-part epoxies and adhesives are tough. However, it’s better to stay prepared. First, read the product’s user manual to know the blend ratios. Then, mix as directed to activate the adhesives.

Pinpoint: Use a paintbrush or a needle tip to pinpoint the glue application.

For durable and stable adhesive bond…

You can harden the substrates at 158° Fahrenheit (70° Celsius) before and after bonding. The procedure will do wonders, but only with acrylic-based adhesives.

To avoid undesirable results:

Some adhesives don’t react with other materials like you want them to. To avoid undesirable reactions like random dissolving, it is essential to mask them properly before working with aggressive adhesives.

Leaded glue residues that have not dried should be cleaned immediately using a lint-free cotton cloth to avoid unpleasant noises.

Clamping for a Hardened Seal:

Sealing pieces firmly is crucial. Use a clamp or tape to hold parts firmly together while the glue solidifies. Curing times can be anything from a few minutes to up to 24 hours. Check your product instructions for accurate details.

FAQs

Below are some frequently asked questions on the best acrylic glue. Let’s have a look.

Does Gorilla Glue work on plexiglass?

Gorilla glass will work on Plexiglass or acrylic. It will make plexiglass bond with plexiglass and Plexiglass with PVC.

Is hot glue suitable for plastic?

Hot and melted glue works well with several types of plastics, giving them a durable bond. It is also used to fasten plastic with several other objects, such as plastic, tiles, and wood. As you’re avoiding any drilling or nailing, you’re also avoiding damaging surfaces. Hot melt glue is also extensively used in preparing various plastic objects.

Which is the strongest glue in the market?

The world’s strongest adhesive is DELO MONOPOX VE403728. This is a modified variant of the high-temperature-resistant DELO MONOPOX HT2860. This epoxy resin creates a dense network during heat curing.

What is the difference between plexiglass and acrylic?

The simple answer to that question is that there is absolutely no difference between them. Acrylic is the usual abbreviation for polymethyl methacrylate, and Plexiglas® is one of the brand names for this material. Unfortunately, the brand name “Plexiglass” has become generic for acrylic over time.

Can I screw into plexiglass?

It is possible to drill or screw into Plexiglass. You should have control over your drilling speed. The faster the drill, the hotter the bit gets. The hot bit will melt the Plexiglass around the hole. The key for successfully drilling screws into Plexiglass is to make the hole bigger than the screw.

How to remove scratches from Plexiglass?

Getting rid of scratches from Plexiglass includes a 600 grit wet sandpaper which will be used for wiping over the scratched area in a circular motion. Repeat till you see the area buffed without an apparent sign of scratch. After that, rub the part thoroughly with a dry 600 grit sandpaper or a lint-free cotton cloth. You might notice a bit of frostiness on your acrylic, but it will disappear soon.

Suggested Read

- What is Polystyrene? | The Definitive Guide

- Step Growth vs Chain Growth Polymerization

- What is Condensation Polymerization? | The Definitive Guide

- Physical Properties of Plastic Materials | The Complete Guide

- Antistatic vs. Static Dissipative Plastics | Which One to Choose?

Final Thoughts

In wrapping up my discussion about Plexiglass glue, I’ve said everything I think is necessary. However, I urge you to exercise extreme caution when selecting adhesives, particularly in any kind of plastic material, with acrylic or Plexiglass being no exception to this rule.

To bolster your understanding of the intricacies of selecting adhesives, particularly for Plexiglass, is to thoroughly read and digest guidebooks or manuals related to the topic. These resources can provide a wealth of information, from the basics to the more advanced concepts.

It’s also beneficial to branch out and explore a variety of materials found online, as the internet is a vast repository of knowledge where you can glean insights from experts around the globe.

By doing so, you would not just grasp the idea on a surface level, but you’ll be able to comprehend the concept in-depth, which will prove helpful in practical applications.

Kindly share your reviews ad thoughts in the comment box.

Quick Navigation

I am building a pond made of rock

The builder will grind an edge on the bottom and sides of the rock so we can insert a PlexiGlass (acrylic) window in the rock frame.

Can you please tell me the best silicone to use for this application?

Or do you suggest another product to use to seal to make it water tight.

Thank you

Gloria King

808-737-1991

Email: glory.king!aol.com

Well, according to my knowledge GE silicone would the best option for that specific application.

I want to water bubble wall joint acrylic bond glu gel taipe

Need to glue a plexiglass to metal frame. What should I use for adhesive.