Hello people; I hope you’re all doing fantastic. Today, I will share a very engaging piece on plastics’ dielectric strength and dielectric properties. So without further ado, let’s get started.

Dielectric Strength of Plastics

The dielectric strength of most plastics typically falls between 100 and 300 kV/cm, averaging at about 200 kV/cm. In contrast, specific chlorinated and additive-enriched polymers showcase dielectric strengths as high as 500 kV/cm. Teflon, renowned for its outstanding chemical and impact resistance, can achieve a remarkable 700 kV/cm.

Most plastics are poor conductors of electricity and resist a current flow, thus called dielectrics or insulators. That is one of the most valuable properties of plastic material and makes them applicable in making products utilized in our day-to-day lives, such as switches & switchboards, wire coatings, light fittings, and other electrical goods and appliances.

As plastics are insulators, when voltage is applied and steadily increased on them, It will eventually reach a point when the electrical properties break down—the breakdown increases an electrical arc across the electrodes, which causes a catastrophic reduction in resistance.

What is Dielectric Strength?

The dielectric strength of plastics or any insulating material can be understood as the ratio of the charge deposited in an insulating material between two metallic plates to the charge stored when a vacuum or air replaces the insulating material. The phenomenon is called electrical permittivity. The dielectric strength of a material showcases its ability to store electrical energy.

The dielectric strength of plastic depends on its type and shape, the field increase rate, and the medium surrounding the insulator. Dielectric strength is derived by a unit kV by mm of thickness.

Which Common Standard Tests Determine Dielectric Strength?

The primary standard tests typically employed to determine dielectric strength include:

ASTM D149-20: This test method gauges the dielectric breakdown voltage and the dielectric strength of insulation materials, such as electrical cables and wires.

IEC 60243-1:2013: This method is employed to ascertain the dielectric strength of solid insulation materials, like plastics and rubbers.

How to Calculate Dielectric Strength?

The most common standard tests to calculate the dielectric strength of plastic materials are ASTM D149 or IEC 60243-1. Below are the methods used for measuring dielectric strength:

- Short time method

- Slow rate of rise method

- Step by step method

Short Time Method

Here, the voltage is applied across the two electrodes and bumped up constantly at a uniform rate (500 V/sec) until the breakdown occurs. The meaning of breakdown is when the voltage punctures the sample or creates decomposition.

Slow Rate of Rise Method

The voltage is applied to the test electrodes at only 50% of the breakdown voltage until breakdown or decomposition happens.

Step By Step Method

The voltage is applied to the electrodes at a predetermined starting voltage in various steps and spans until the breakdown.

Interesting Read – 7 Best UV Resistant Plastics For Outdoor Applications

Applications

- Dielectric material for capacitors used in radio and other electrical equipment.

- Development of material for energy storage solutions.

- Used by circuit designers to evaluate different printed-circuit-board (PCB) materials.

- Thin films in the high-speed digital microprocessor.

Factors Affecting Dielectric Strength

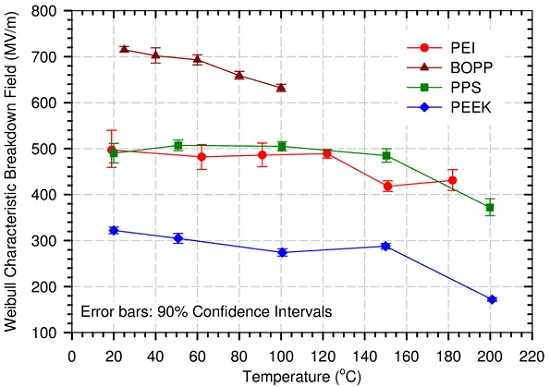

The graph illustrates the Weibull Characteristic Breakdown Field, measured in MV/m, for four different polymers across a temperature range of 0 to 220°C. The polymers examined are PEI (Polyetherimide), BOPP (Biaxially Oriented Polypropylene), PPS (Polyphenylene Sulfide), and PEEK (Polyether Ether Ketone).

At 0°C, PEI has the highest breakdown field, around 750 MV/m, but it decreases gradually to approximately 600 MV/m by 220°C. BOPP starts at about 725 MV/m and shows a slight dip, stabilizing near 675 MV/m. PPS starts near 600 MV/m, remains relatively steady until 140°C, and then dips to around 550 MV/m by 220°C.

PEEK displays the most notable decline, starting at 400 MV/m and plummeting to slightly above 100 MV/m by the end of the temperature spectrum. Each data point has associated error bars indicating 90% confidence intervals, which showcases the potential variability in measurements.

The data shows that as temperature increases, the breakdown field for these polymers tends to decrease, with PEEK being the most affected by rising temperatures.

- Hold on tight because things are about to get heated! The dielectric strength of plastics tends to drop as temperatures rise, roughly moving in an inverse relationship to absolute temperature. Yet, it’s fascinating that dielectric strength remains remarkably unaffected by temperature fluctuations.

- But wait, there’s more! Mechanical stress can significantly impact dielectric strength, as it introduces internal flaws in insulators, creating leakage pathways and weakening their dielectric fortitude.

- And here’s the twist: manufacturing quirks can significantly affect a plastic’s dielectric strength. Even the tiniest defects can pack a punch from weld lines in injection molding to flow lines in compression molding. These seemingly insignificant imperfections can slash an insulator’s dielectric strength by 30-40%!

Polar VS Non-Polar Plastics

A plastic material’s dielectric strength and electrical properties heavily depend on its structure. The structure of a polymer decides whether it is polar or non-polar, thereby determining its properties.

Polar polymers (PMMA, PC, Nylon, PVC, etc.) are comprised of dipoles created due to the imbalance in the distribution of electrons. These dipoles align themselves in the presence of the electric field. Thus dipole polarization is designed for the polymer, making them average-performing insulators.

On the other hand, Non-polar polymers (PS, PTFE, PP, PE) have symmetrical molecules and are entirely covalent. There is no presence of polar dipoles in them, and thus the attendance of the electric field doesn’t align with the dipoles. However, the movement of electrons in the direction of the electric field will erupt in a slight electron polarization. These polymers have elevated resistivities and low dielectric constant.

Polar plastics have the propensity to absorb moisture from the atmosphere. Moisture can raise the dielectric constant and lower the resistivity. As the temperature rises, polymer chains move faster, and the dipoles are aligned more quickly.

Non-polar plastics do not affect the rising atmosphere and moisture.

Dielectric Strength Values of Polymers

Polymer Name | Minimum Value (kV/mm) | Maximum Value (kV/mm) |

| ABS – Acrylonitrile Butadiene Styrene | 15.7 | 34 |

| ABS Flame Retardant | 24 | 35.4 |

| ABS High Heat | 12 | 20 |

| ABS High Impact | 12 | 20 |

| ABS/PC Blend – Acrylonitrile Butadiene Styrene/Polycarbonate Blend | 15 | 70 |

| ABS/PC Blend 20% Glass Fiber | 29.9 | 30 |

| Amorphous TPI Blend, Ultra-high heat, Chemical Resistant (Standard Flow) | 54 | 54 |

| Amorphous TPI, Moderate Heat, Transparent | 17 | 17 |

| Amorphous TPI, Moderate Heat, Transparent (Food Contact Approved) | 17 | 17 |

| Amorphous TPI, Moderate Heat, Transparent (Mold Release grade) | 14 | 14 |

| Amorphous TPI, Moderate Heat, Transparent (Powder form) | 17 | 17 |

| ASA – Acrylonitrile Styrene Acrylate | 40 | 105 |

| ASA/PC Blend – Acrylonitrile Styrene Acrylate/Polycarbonate Blend | 80 | 95 |

| ASA/PC Flame Retardant | 90 | 90 |

| CA – Cellulose Acetate | 8 | 15 |

| CAB – Cellulose Acetate Butyrate | 10 | 16 |

| CP – Cellulose Proprionate | 12 | 18 |

| CPVC – Chlorinated Polyvinyl Chloride | 50 | 60 |

| ECTFE – Ethylene ChloroTriFluoroEthylene | 14 | 14 |

| ETFE – Ethylene Tetrafluoroethylene | 7.87 | 7.87 |

| EVA – Ethylene Vinyl Acetate | 27 | 28 |

| FEP – Fluorinated Ethylene Propylene | 22 | 79 |

| HDPE – High Density Polyethylene | 17 | 24 |

| HIPS – High Impact Polystyrene | 12 | 24 |

| HIPS Flame Retardant V0 | 33 | 35 |

| Ionomer (Ethylene-Methyl Acrylate Copolymer) | 40 | 40 |

| LCP – Liquid Crystal Polymer | 32 | 39 |

| LCP Glass Fiber-reinforced | 22 | 30 |

| LCP Mineral-filled | 26 | 35 |

| LDPE – Low Density Polyethylene | 16 | 28 |

| MABS – Transparent Acrylonitrile Butadiene Styrene | 34 | 37 |

| PA 11 – (Polyamide 11) 30% Glass fiber reinforced | 40 | 40 |

| PA 11, Conductive | 24 | 55 |

| PA 11, Flexible | 24 | 55 |

| PA 11, Rigid | 24 | 55 |

| PA 12 (Polyamide 12), Conductive | 24 | 55 |

| PA 12, Fiber-reinforced | 24 | 55 |

| PA 12, Flexible | 24 | 55 |

| PA 12, Glass Filled | 24 | 55 |

| PA 12, Rigid | 24 | 55 |

| PA 46 – Polyamide 46 | 15 | 25 |

| PA 46, 30% Glass Fiber | 25 | 35 |

| PA 6 – Polyamide 6 | 10 | 20 |

| PA 6-10 – Polyamide 6-10 | 16 | 26 |

| PA 66 – Polyamide 6-6 | 20 | 30 |

| PA 66, 30% Glass Fiber | 25 | 25 |

| PA 66, 30% Mineral filled | 25 | 30 |

| PA 66, Impact Modified, 15-30% Glass Fiber | 11.8 | 21 |

| PA 66, Impact Modified | 18 | 90 |

| PA 66, Carbon Fiber, Long, 30% Filler by Weight | 1.3 | 1.3 |

| PAI – Polyamide-Imide | 23.6 | 24 |

| PAI, 30% Glass Fiber | 27.6 | 34 |

| PAR – Polyarylate | 17 | 17 |

| PARA (Polyarylamide), 30-60% glass fiber | 23.7 | 30 |

| PBT – Polybutylene Terephthalate | 15 | 30 |

| PBT, 30% Glass Fiber | 50 | 50 |

| PC (Polycarbonate) 20-40% Glass Fiber | 20 | 20 |

| PC (Polycarbonate) 20-40% Glass Fiber Flame Retardant | 17 | 38 |

| PC – Polycarbonate, high heat | 16 | 35 |

| PCTFE – Polymonochlorotrifluoroethylene | 21 | 24 |

| PE – Polyethylene 30% Glass Fiber | 19.7 | 19.7 |

| PEEK – Polyetheretherketone | 20 | 20 |

| PEEK 30% Carbon Fiber-reinforced | 18.5 | 19 |

| PEEK 30% Glass Fiber-reinforced | 15 | 24 |

| PEI – Polyetherimide | 28 | 33 |

| PEI, 30% Glass Fiber-reinforced | 25 | 30 |

| PEI, Mineral Filled | 20 | 25 |

| PEKK (Polyetherketoneketone), Low Cristallinity Grade | 23.6 | 23.6 |

| PESU – Polyethersulfone | 16 | 80 |

| PESU 10-30% glass fiber | 14.6 | 40 |

| PET – Polyethylene Terephthalate | 60 | 60 |

| PET, 30% Glass Fiber-reinforced | 16.8 | 22.5 |

| PETG – Polyethylene Terephthalate Glycol | 45 | 45 |

| PFA – Perfluoroalkoxy | 2.1 | 2.2 |

| PGA – Polyglycolides | 34 | 80 |

| PI – Polyimide | 22 | 27.6 |

| PMMA – Polymethylmethacrylate/Acrylic | 15 | 22 |

| PMMA (Acrylic) High Heat | 18.7 | 20 |

| PMMA (Acrylic) Impact Modified | 15 | 60 |

| PMP – Polymethylpentene | 28 | 30 |

| PMP 30% Glass Fiber-reinforced | 23.6 | 23.6 |

| PMP Mineral Filled | 23.6 | 23.6 |

| POM – Polyoxymethylene (Acetal) | 13.8 | 20 |

| POM (Acetal) Impact Modified | 19 | 19 |

| POM (Acetal) Low Friction | 16 | 16 |

| PP – Polypropylene 10-20% Glass Fiber | 30 | 45 |

| PP, 10-40% Mineral Filled | 30 | 70 |

| PP, 10-40% Talc Filled | 30 | 70 |

| PP, 30-40% Glass Fiber-reinforced | 30 | 45 |

| PP (Polypropylene) Copolymer | 20 | 28 |

| PP (Polypropylene) Homopolymer | 20 | 28 |

| PP, Impact Modified | 20 | 28 |

| PPA – Polyphthalamide | 20.8 | 20.9 |

| PPA, 30% Mineral-filled | 20 | 22 |

| PPA, 33% Glass Fiber-reinforced | 20 | 22 |

| PPA, 33% Glass Fiber-reinforced – High Flow | 18 | 20 |

| PPA, 45% Glass Fiber-reinforced | 22 | 24 |

| PPE – Polyphenylene Ether | 20 | 22 |

| PPE, 30% Glass Fiber-reinforced | 22 | 22 |

| PPE, Flame Retardant | 16 | 25 |

| PPE, Impact Modified | 1 | 1.1 |

| PPS – Polyphenylene Sulfide | 11 | 24 |

| PPS, 20-30% Glass Fiber-reinforced | 13.8 | 17 |

| PPS, 40% Glass Fiber-reinforced | 17 | 17 |

| PPS, Glass fiber & Mineral-filled | 13 | 13 |

| PPSU – Polyphenylene Sulfone | 14.2 | 20 |

| PS (Polystyrene) 30% glass fiber | 15 | 19.7 |

| PS (Polystyrene) Crystal | 16 | 28 |

| PSU – Polysulfone | 15 | 10 |

| PSU, 30% Glass finer-reinforced | 16.9 | 40 |

| PTFE – Polytetrafluoroethylene | 17 | 24 |

| PTFE, 25% Glass Fiber-reinforced | 20 | 20 |

| PVC, Plasticized | 10 | 30 |

| PVC, Plasticized Filled | 10 | 30 |

| PVC Rigid | 10 | 40 |

| PVDF – Polyvinylidene Fluoride | 10 | 27 |

| SAN – Styrene Acrylonitrile | 12 | 24 |

| SAN, 20% Glass Fiber-reinforced | 19.7 | 20 |

| SMA – Styrene Maleic Anhydride | 16 | 16 |

| SMA, 20% Glass Fiber-reinforced | 21 | 21 |

| SMMA – Styrene Methyl Methacrylate | 19.7 | 19.7 |

| UHMWPE – Ultra High Molecular Weight Polyethylene | 28 | 28 |

Engaging Read – What is the Glass Transition Temperature of Plastics?

Dielectric Constant Values of Mainstream Polymers

| Polymer Name | Min Value | Max Value |

ABS – Acrylonitrile Butadiene Styrene | 2.7 | 3.2 |

ABS Flame Retardant | 2.8 | 3 |

| ABS High Heat | 2.4 | 5 |

| ABS High Impact | 2.4 | 5 |

ABS/PC Blend – Acrylonitrile Butadiene Styrene/Polycarbonate Blend | 2.9 | 3.2 |

ABS/PC Blend 20% Glass Fiber | 3.1 | 3.2 |

Amorphous TPI Blend, Ultra-high heat, Chemical Resistant (Standard Flow) | 3.5 | 3.5 |

ASA – Acrylonitrile Styrene Acrylate | 3.3 | 3.8 |

ASA/PC Blend – Acrylonitrile Styrene Acrylate/Polycarbonate Blend | 3 | 3.4 |

ASA/PC Flame Retardant | 3.2 | 3.2 |

CA – Cellulose Acetate | 3 | 8 |

CAB – Cellulose Acetate Butyrate | 3 | 7 |

CP – Cellulose Proprionate | 3 | 4 |

CPVC – Chlorinated Polyvinyl Chloride | 3 | 6 |

| ECTFE | 2.57 | 2.59 |

ETFE – Ethylene Tetrafluoroethylene | 2.6 | 2.6 |

EVA – Ethylene Vinyl Acetate | 2.5 | 3 |

EVOH – Ethylene Vinyl Alcohol | 4.8 | 5.6 |

FEP – Fluorinated Ethylene Propylene | 2.1 | 2.1 |

HDPE – High Density Polyethylene | 2.3 | 2.3 |

HIPS – High Impact Polystyrene | 2.4 | 4.8 |

HIPS Flame Retardant V0 | 2 | 3 |

LCP – Liquid Crystal Polymer | 3.3 | 3.3 |

LCP Glass Fiber-reinforced | 3 | 4 |

LCP Mineral-filled | 3 | 5.9 |

LDPE – Low Density Polyethylene | 2.3 | 2.3 |

LLDPE – Linear Low Density Polyethylene | 2.3 | 2.3 |

MABS – Transparent Acrylonitrile Butadiene Styrene | 2.8 | 3 |

PA 11 – (Polyamide 11) 30% Glass fiber reinforced | 4.8 | 4.8 |

PA 11, Conductive | 3 | 9 |

| PA 11, Flexible | 3 | 9 |

| PA 11, Rigid | 3 | 9 |

PA 12 (Polyamide 12), Conductive | 3 | 9 |

PA 12, Fiber-reinforced | 3 | 9 |

| PA 12, Flexible | 3 | 9 |

PA 12, Glass Filled | 3 | 9 |

| PA 12, Rigid | 3 | 9 |

PA 46 – Polyamide 46 | 3.4 | 3.8 |

PA 46, 30% Glass Fiber | 4 | 4.6 |

PA 6 – Polyamide 6 | 4 | 5 |

PA 6-10 – Polyamide 6-10 | 3 | 4 |

PA 66 – Polyamide 6-6 | 4 | 5 |

PA 66, 30% Glass Fiber | 3.5 | 5.6 |

PA 66, 30% Mineral filled | 4 | 5 |

PA 66, Impact Modified, 15-30% Glass Fiber | 3.4 | 4.2 |

PA 66, Impact Modified | 2.9 | 5 |

PAI – Polyamide-Imide | 3.9 | 7.3 |

PAI, 30% Glass Fiber | 4.2 | 6.5 |

PAR – Polyarylate | 3.3 | 3.3 |

PARA (Polyarylamide), 30-60% glass fiber | 3.9 | 4.5 |

PBT – Polybutylene Terephthalate | 2.9 | 4 |

PBT, 30% Glass Fiber | 3 | 4 |

PC (Polycarbonate) 20-40% Glass Fiber | 3 | 3.5 |

PC (Polycarbonate) 20-40% Glass Fiber Flame Retardant | 3 | 3.8 |

PC – Polycarbonate, high heat | 2.8 | 3.8 |

PC/PBT Blend – Polycarbonate/Polybutylene Terephthalate Blend | 2.95 | 3.14 |

PC/PBT blend, Glass Filled | 3.3 | 3.9 |

PCTFE – Polymonochlorotrifluoroethylene | 2 | 3 |

PE – Polyethylene 30% Glass Fiber | 2.7 | 2.8 |

PEEK – Polyetheretherketone | 3.2 | 3.2 |

PEEK 30% Carbon Fiber-reinforced | 3.2 | 3.4 |

PEEK 30% Glass Fiber-reinforced | 3.3 | 4.2 |

PEI – Polyetherimide | 3.1 | 3.2 |

PEI, 30% Glass Fiber-reinforced | 3 | 4 |

PEI, Mineral Filled | 3 | 4 |

PEKK (Polyetherketoneketone), Low Cristallinity Grade | 3.3 | 3.3 |

PESU – Polyethersulfone | 3.5 | 4.1 |

PESU 10-30% glass fiber | 4.2 | 4.3 |

PET – Polyethylene Terephtalate | 3 | 4 |

PET, 30% Glass Fiber-reinforced | 3 | 4 |

PETG – Polyethylene Terephtalate Glycol | 3 | 4 |

PFA – Perfluoroalkoxy | 2.1 | 2.1 |

| PI – Polyimide | 3.1 | 3.55 |

PMMA – Polymethylmethacrylate/Acrylic | 2 | 5 |

PMMA (Acrylic) High Heat | 3.2 | 4 |

PMMA (Acrylic) Impact Modified | 2.9 | 3.7 |

PMP – Polymethylpentene | 2.1 | 3.6 |

PMP 30% Glass Fiber-reinforced | 2.4 | 2.4 |

PMP Mineral Filled | 2.3 | 2.3 |

POM – Polyoxymethylene (Acetal) | 3.3 | 4.7 |

POM (Acetal) Impact Modified | 4 | 4.3 |

POM (Acetal) Low Friction | 3 | 4 |

PP – Polypropylene 10-20% Glass Fiber | 2.6 | 2.6 |

PP, 10-40% Mineral Filled | 2.3 | 2.3 |

PP, 10-40% Talc Filled | 2.3 | 2.3 |

PP, 30-40% Glass Fiber-reinforced | 2.6 | 2.6 |

PP (Polypropylene) Copolymer | 2.3 | 2.3 |

PP (Polypropylene) Homopolymer | 2.3 | 2.3 |

PP, Impact Modified | 2.3 | 2.3 |

PPA – Polyphthalamide | 4.3 | 4.3 |

PPA, 30% Mineral-filled | 4 | 4.2 |

PPA, 33% Glass Fiber-reinforced | 4.4 | 4.6 |

PPA, 33% Glass Fiber-reinforced – High Flow | 3.7 | 3.9 |

PPA, 45% Glass Fiber-reinforced | 4.4 | 4.6 |

PPE – Polyphenylene Ether | 2.7 | 2.7 |

PPE, 30% Glass Fiber-reinforced | 2.9 | 2.9 |

PPE, Flame Retardant | 2.7 | 2.7 |

PPS – Polyphenylene Sulfide | 3 | 3.3 |

PPS, 20-30% Glass Fiber-reinforced | 3.3 | 3.8 |

PPS, 40% Glass Fiber-reinforced | 4 | 4 |

PPS, Glass fiber & Mineral-filled | 5 | 5 |

PPSU – Polyphenylene Sulfone | 3.4 | 3.5 |

PS (Polystyrene) 30% glass fiber | 2.5 | 2.5 |

PS (Polystyrene) Crystal | 2.4 | 2.7 |

| PS, High Heat | 2.4 | 2.7 |

PSU – Polysulfone | 3 | 3.2 |

PSU, 30% Glass finer-reinforced | 3.6 | 3.7 |

PTFE – Polytetrafluoroethylene | 2.1 | 2.1 |

PTFE, 25% Glass Fiber-reinforced | 3 | 3 |

| PVC, Plasticized | 3 | 5 |

PVC, Plasticized Filled | 3 | 5 |

| PVC Rigid | 3 | 4 |

PVDC – Polyvinylidene Chloride | 3 | 6 |

PVDF – Polyvinylidene Fluoride | 6 | 9 |

SAN – Styrene Acrylonitrile | 2.5 | 3.4 |

SAN, 20% Glass Fiber-reinforced | 3.2 | 3.8 |

SMA – Styrene Maleic Anhydride | 2.8 | 2.8 |

SMA, 20% Glass Fiber-reinforced | 3.3 | 3.3 |

SMMA – Styrene Methyl Methacrylate | 3.2 | 3.2 |

SRP – Self-reinforced Polyphenylene | 3.1 | 3.1 |

UHMWPE – Ultra High Molecular Weight Polyethylene | 2.3 | 2.3 |

Fascinating Read – What is the Density of Plastics? | The Complete Guide

FAQs

Get ready to dive headfirst into the electrifying world of the dielectric strength of polymers! We’ve compiled a list of sizzling FAQs to quench your thirst for knowledge. Come on, let’s take a look!

What is the formula of dielectric strength?

M1L2T−2Q−1.

What is the dielectric strength of Bakelite?

300-550 Kv/inch

Why is plastic an electrical insulator?

In layman’s language, they don’t possess free electrons moving around, a phenomenon also called delocalized electrons. That makes them bad conductors of electricity and heat, which gives them the property of great insulators.

How can polymers be made electrically conductive?

The two main methods used to make insulators electrically conductive – Chemical synthesis and electro (co) polymerization. Chemical synthesis means connecting the carbon-carbon bond of monomers by placing the simple monomers under various conditions, such as heating, light exposure pressing, and catalyst.

Suggested Read

- What is Compressive Strength of Plastics | The Complete Guide

- Mechanical Properties of Plastic Materials | The Definitive Guide

- Physical Properties of Plastic Materials | The Complete Guide

- Thermal Properties of Plastics | The Ultimate Guide

- What is Processing and Drying Temperatures of Plastics

- Polycarbonate VS Plastic Lenses | A Complete Analysis

Final Thoughts

Dielectric strength, a measure of a plastic’s ability to resist electrical breakdown, is critical for insulating materials. Plastics, given their diverse chemical structures, exhibit varying dielectric strengths. Temperature, molecular arrangement, and impurities can impact this property.

As observed, some plastics maintain a relatively stable dielectric strength across temperature ranges, while others might see significant reductions.

Choosing the right plastic based on its dielectric strength, tailored to specific environmental conditions, is crucial for ensuring the safety and efficiency of electronic and electrical systems. Thus, a comprehensive understanding of a plastic’s dielectric properties is essential for optimal application.

Have a wonderful day.

Quick Navigation

The difference between dielectric strength and dielectric constant was very well explained here.

Thanks, jeff, It took a lot of digging through books to understand the difference between the two topics.