Hello people. I hope you’re all doing well. Today I’m going to share a short and simple guide on nylon melt point, repeat unit, and related attributes.

Nylon Melting Point

The melting point of nylon is typically around 220-265 degrees Celsius (428-509 degrees Fahrenheit). At this temperature, the solid nylon material transforms into a molten state, allowing it to be molded or shaped before solidifying again upon cooling.

The melting point can vary depending on the type of nylon and the specific manufacturing process used to produce it.

The melting point of nylon varies depending on its type and the particular manufacturing method employed.

For instance, Nylon 6 has a lower melting point, approximately 215°C (419°F), in contrast to Nylon 66, which has a higher melting point of roughly 265°C (509°F).

Nylon 6 has a lower melting point of around 215°C (419°F) compared to nylon 66, which has a higher melting point of around 265°C (509°F).

The significance of the melting point of nylon lies in its ability to dictate how the material can be utilized and fabricated.

For instance, in the production of textiles, melting nylon fibers is a crucial step in spinning them into thread.

Nylon is also extensively utilized in Automotive, electrical, electronics, healthcare, pipes, etc.

This involves extruding the fibers through heated spinnerets, with the temperature set just above the melting point of nylon.

Upon cooling, the melted nylon solidifies into a seamless, elongated thread, which can be further refined to create a range of textile products.

Similarly, nylon is often used in engineering applications to make parts and components requiring high precision and strength.

These parts may be produced using injection molding, which involves heating the nylon to its melting point and then injecting it into a mold, where it solidifies and takes on the shape of the mold.

The part is then removed from the mold and finished as needed.

Nylon’s thermal properties are another aspect where its melting point holds significance.

Under high temperatures, nylon may undergo degradation and lose its inherent characteristics.

The temperature threshold for this to happen can differ based on the type of nylon and the surrounding conditions.

Generally, nylon degradation can commence at temperatures exceeding its melting point.

As a result, exercising caution and monitoring processing temperature is crucial to prevent any adverse effects when working with nylon.

Nylon General Attributes

Below are the tables mentioning the general properties of nylon.

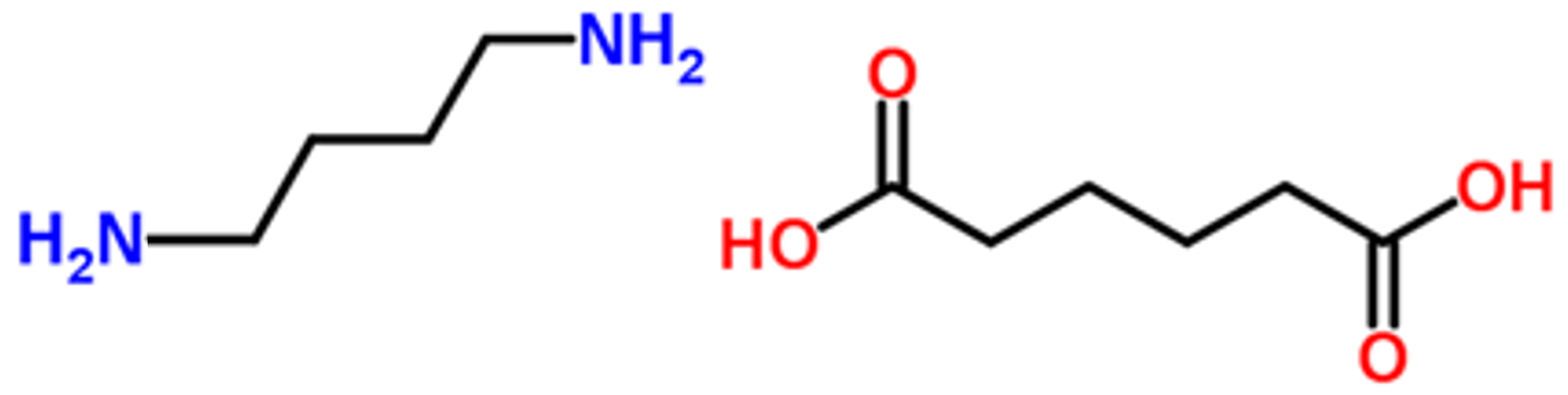

| Identification of Monomers | |

| Common Names |

diaminobutane + adipic acid

|

| SMILES |

OC(=O)CCCCC(=O)O.NCCCCN

|

| Std. InChI |

WNLRTRBMVRJNCN-UHFFFAOYSA-N.KIDHWZJUCRJVML-UHFFFAOYSA-N

|

| CAS # | – |

| Structure |  |

| Thermophysical Properties – Experimental Data | ||

| Property | Unit |

Preferred-Value/Range

|

| Density | g mL-1 | < 1.18 |

| Melt Point | C°/ F° | 268/514 |

| Molar Volume | mL mol-1 | |

| Glass Transition Temperature | K | 353 |

| Solubility Parameter | MPa1/2 | |

| Molar Cohesive Energy | J mol-1 | |

| Entanglement Molecular Weight Me | g mol-1 | |

| Index of Refraction n | none | |

Interesting Read – ABS Melting Point | The Ultimate Guide

| Thermo-Physical Properties – Calculated Data | |||

| Property | Unit | Value/Range | Preferred |

| Molecular Weight of Repeat unit | g mol-1 | 198.27 | – |

| Molar Volume | mL mol-1 | 176-1816 | 179 |

| Van-der-Waals Volume | mL mol-1 | 117.1 | – |

| Solubility Parameter | MPa1/2 | 24.4 – 27.3 | 26.6 |

| Molar Cohesive Energy | J mol-1 | 108000 – 141000 | 126000 |

| Molar Heat Capacity | J (mol K)-1 | 286-299 | 292 |

| Glass Transition Temperature | K | 329-360 | 345 |

| Entanglement Molecular Weight | g mol-1 | – | – |

| Index of Refraction | none | 1.51 – 1.53 | 1.52 |

General Properties of Nylon Plastic

- Interesting strength and stiffness at relatively high temperatures.

- Outstanding electrical insulation properties

- Low dimensional stability

- Great impact strength (even at low temperatures)

- Good fatigue resistance

- Fantastic oil and fuel resistance

- Dyeing is a must before processing

- Good fatigue resistance

- Meager dimensional stability

- Susceptible to attacks from mineral acids and polar solvents

- The nylon melt point is relatively high because nylons are polyamides formed by an amine that reacts with an acid. The amide group is responsible for Nylon’s high melting point, strength, and natural harmony with moisture.

- Nylon can easily be flame retarded, which is quite rare in thermoplastics.

Engaging Read – PVC Melting Point | The Ultimate Guide

Advantages and Disadvantages

Advantages

- Smooth processing and easy machining.

- Outstanding wear-resistance and abrasion

- Excellent tensile and compressive strength.

- Super lightweight compared to other thermoplastics. 1/7th in weight compared to mainstream thermoplastics such as polypropylene, polystyrene, polycarbonate, etc.

- Intricate designs are easily achievable.

- Excellent dust and dirt resistance.

Disadvantages

- The infamous high melting temperature can become a nuisance in certain applications.

- Highly flammable. Catches fire easily in an open fire.

- Not compatible with UV exposure. Additional UV-proof coating must be added for UV protection.

Applications

Typical Applications

- Wheels

- Gloves

- Toothbrushes

- Medical implants

- Electrical connectors

- Fishing lines

- Tents

- Gears

- Tennis racket strings

- Guitar strings and pics

- Tents

- Wear pads

Construction: tubes, pipes, sheet ods, pipes, screws, plumbing fittings, industrial hammerheads, crane pads, etc.

Electrical: Switchgear, circuit insulation board, machine guards, seals, electronic test equipment, jigs & fixtures, rotor slot wedges, gears, replacement components, wear strips & chain guards.

Automotive: door handles & radiator grills.

Suggested Read –

- The Best Polycarbonate Glue | How to Glue Polycarbonate Properly?

- What are the Top 5 High Tensile Strength Plastics?

- What is PETG Material? | The Definitive Guide

- 7 Types of Plastics | An Helpful Illustrated Guide

- What is Processing and Drying Temperatures of Plastics

- What is Polypropylene Material? | The Ultimate Guide

FAQs

Which is more water-resistant? Nylon or Polyester.

Polyester is more water-resistant than Nylon. However, none of them is completely waterproof. Nylon has a moisture regain level of 4%, whereas polyester has a moisture regain of 0.4%. Meaning polyester is more hydrophobic than Nylon.

How do you clean Nylon Plastic?

It is quite easy to clean but should be done carefully because nylon resists absorbing moisture and dries easily. Handwashing is the easiest and safest way to clean Nylon products. Rinsing with cool water until the water is no longer soapy and doesn’t wring.

What is the reason behind Nylon’s high melting point?

Amide groups form nylon with more intermolecular interaction making the attractive force high. That actor makes both the melting point and mechanical properties more robust.

What is the main difference between Nylon and polypropylene?

Nylon and polypropylene are drastically different materials from each other. Polypropylene looks and feels very dull compared to nylon which feels silky. Polypropylene is a prime replacement for wool and cotton, whereas nylon replaces silk.

What is the material density of Nylon?

1.15 g/cm3.

Conclusion

In conclusion, understanding the melting point of nylon is crucial for various applications, including manufacturing processes and material selection. Nylon exhibits excellent thermal stability with a melting point ranging from 220 to 265 degrees Celsius.

This property enables it to withstand high temperatures without losing its structural integrity.

Moreover, the ability to melt and solidify makes nylon easily moldable, allowing for versatile use in textiles, automotive, and electronics industries.

Overall, the knowledge of nylon’s melting point empowers engineers and designers to optimize its performance in diverse settings.

Kindly share your devices in the comment section.

Quick Navigation