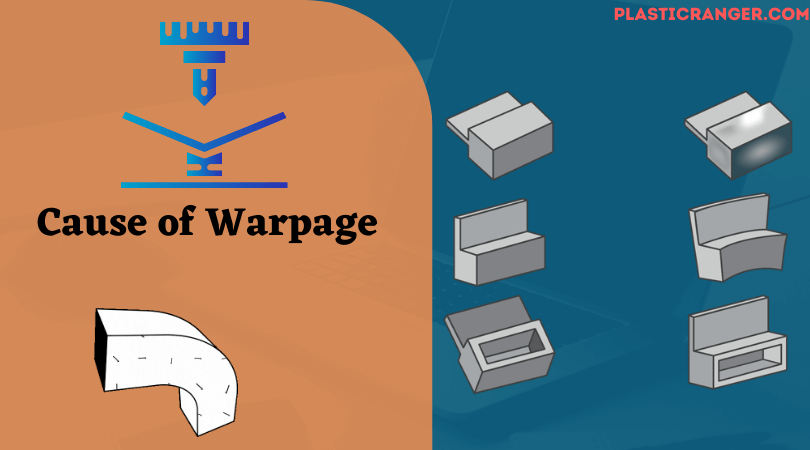

Warpage is a common and extremely stubborn problem to get rid of regularly seen in injection molded parts. Professionals working with injection molding machines will know what I’m talking about. Let’s see a bit more about that.

What is Warpage?

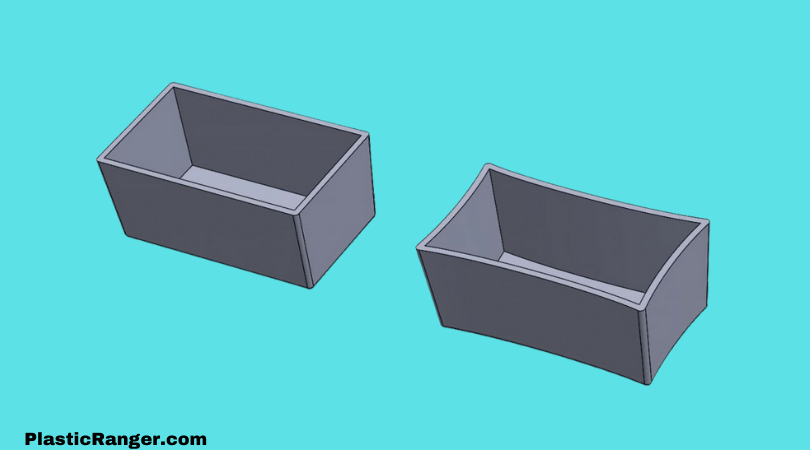

Warpage is an unconventional bending or twisting out of the shape of a plastic part that is easily recognizable. The cause of unnatural bent can be heating, cooling, or dampening.

The molded-in residual stress is the prime cause of warpage, caused by contrasting shrinkage in the molded part’s material.

One doesn’t need technical knowledge; an average consumer can notice unconventional bending or twisting.

Unintentional bending can be prevented in multiple ways, especially if the molded part was made by injection molding.

However, finding out the cause of the warpage is the most important part, often overlooked.

There are three main ways to determine the causes of Warpage

- How much your part warp

- Warpage direction

- Understand the mating requirements of your parts

Cause for Warpage in Plastic

Plastic Shrinkage

Material shrinking during and after the manufacturing site is the prime reason for warpage in injection molded plastic components. But before getting into molded components shrinkage, we should know how different plastic materials shrink.

We must start with the basics and understand how plastics melt and cool. Plastics’ melting and cooling are completely dependent on polymer and the presence of fiber reinforcements.

- Amorphous Materials

- Semi-crystalline Materials

Amorphous Materials

The most popular amorphous materials include ABS, polystyrene, and polycarbonate.

Amorphous materials have a unique, intertwined molecular orientation in their natural state. When amorphous materials melt, their molecules weaken and move away from each other.

Additionally, the friction causes single molecules to unwind and line up with the flow position.

The molecules will relax and return to the state of orientation only when the flow stops.

The molecules force to squeeze them together until the temperature is dropped to their cooling point.

In turn, the relaxation effect caused by the molecules causes the shrinkage in the flow direction.

Semi-crystalline Materials

The most commonly used Semi-crystalline materials include polyethylene, polypropylene, and PET plastic are opposite to amorphous materials in their structure and nature.

They have thoroughly ordered and tightly packed up molecules. When the molecules melt, their crystalline structure loosens and lines up to the maximum flow direction.

When the molecules are cooled to their cooling point rather than relaxing, they again try to re-align with the flow direction and recrystallize tighter than their original state.

The main impact is felt on the perpendicular side of the flow.

Types of Shrinkages

What is warpage? A variation in shrinkage, that’s it. In simple words, shrinkage extending in all directions uniformly becomes smaller but retains its shape.

However, any difference in the element’s directions will lead to internal stresses, and if these stresses surpass the component’s structural integrity, a warp will be formed in the ejected component.

There are three shrinkage types. Let’s dive into them.

Regional

Regional shrinkage occurs anywhere between the regions closest to the gate and regions close to the end of the fill. The variance should be easily visible between the thickest and thinnest parts of the affected region.

One thing is for sure one region should be shrinking more than another.

Via the Thickness

When there’s shrinkage on the part’s cross-section, the shrinkage’s top part differs significantly from the bottom.

The variation can force the part to bend and shrink from the side.

Directional

Although shrinkage varies from molecule to molecule and fiber alignment to fiber alignment, it can sometimes occur due to the materials’ orientation.

It happens differently in both amorphous and crystalline materials.

As mentioned earlier, amorphous materials shrink more in the direction parallel to the flow; conversely, crystalline materials tend to have their shrinkage perpendicular to the flow direction.

Plastic Shrinkage Rates

General Plastics | Shrinkage Rate (%) | |

| Raw Material | Add. 30% GF | |

| LDPE | 2 | 0.5 |

| HDPE | 2 | 0.4 |

| PP | 1.8 | 0.4 |

| PS | 0.6 | 0.1 |

| PVC | 0.4 | 0.1 |

| PMMA | 0.5 | 0.1 |

| ABS | 0.6 | 0.1 |

Engineering Plastics | Shrinkage Rate (%) | |

| Raw Material | Add. 30% GF | |

| NY6 | 1.5 | 0.4 |

| NY66 | 1.5 | 0.4 |

| PBT | 2 | 0.4 |

| POM | 2.5 | 0.5 |

| PC | 0.6 | 0.1 |

| PPO | 0.6 | 0.1 |

Why Does Warpage Variation Happen?

There are five common reasons for variations in shrinkage rates, which can cause warpage. Let’s discuss those reasons in detail.

- Cooling Rates

- Orientation Due to Filling

- Mold Restraint

- Temperature Differences via Thickness

- Thickness Variations and Uneven Packing

- Products Shape and form

Engaging Read – Types of Gates for Injection Molding | Applications of Gate Designs

Cooling Rates

Semi-crystalline materials have a high cooling rate, which gives less time for the crystalline structure to form. The effect decreases the volume of shrinkage.

The same principle is applied to amorphous materials; the effect is minuscule compared to crystalline materials.

Orientation Due to Filling

Orientation due to the filling can be attributed to polymer molecules caused by shear stress during flow. But when the polymer is at a high temperature and pressure is removed, orientation will be relaxed.

In the same principle, when applied to amorphous materials, there is more shrinkage parallel to the flow. And for crystalline materials, shrinkage will occur perpendicular to the flow.

Mold Restraint

while the component is in the mold, it can’t shrink within its surface but can shrink directly perpendicular to its thickness, resulting in more shrinkage in the region.

After ejection, these accumulated stresses relax as the component cools down and creates a warpage.

Mold restraint is very dependent on materials, more than it is dependent on anything else. Materials that tend to relax more slowly have higher linear shrinkage.

Temperature Differences via Thickness

The mold temperature on the side of the cross-section will play an important role here. If the temperature is different on both sides, shrinkage will not be uniform.

Simply put, the plane on the other side will shrink more, making it tinier than the other side, making a bending movement, and eventually turning into a warpage in plastic materials.

Thickness Variations and Uneven Packing

When there is a visible variation in the component’s thickness, thicker areas will naturally take longer to cool, resulting in shrinkage.

Similar things can be noticed in the areas far from the gate. If a consistent packing profile is utilized, areas closer to the gate will be denser and cool at a different speed.

Products Shape and form

Product design can be an unrecognizable reason for mold warpage. The component design can be a reason for multiple filling patterns resulting in shrinking plastic throughout the cavity.

Inconsistent shrink rate is also a reason for warpage to occur, especially in the areas where there is a high level of pressure loss and gain.

FAQs

Below are the frequently asked questions on warpage injection molding. Let’s dig deep to know more.

What are other common injection molding defects other than Warpage?

Below are the most common injection molding defects:

- Flow Lines

- Sink Marks

- Vacuum Voids

- Surface Delamination

- Weld Lines

- Warping

- Short Shots

- Burn Marks

What causes part warpage?

Part warpage is caused by mold restraint or (lack of mold restraint through the thickness of the part). The difference in shrinkage between the in-plane and thickness directions can cause warpage, particularly in the corners of the part, because these are sometimes thicker than the general wall thickness.

What is the difference between Warpage and sink marks in injection molding?

As established, easier warpage in plastics is an unconventional bending or twisting out of the shape of an easily recognizable plastic part. The cause of unnatural bent can be heating, cooling, or dampening.

On the other hand, sink marks are areas in a molded part where the surface is deformed into a depression. It typically occurs in the thicker read of a part and is caused by uneven cooling.

How can you avoid warpage?

Ensure sufficient time for cooling and that the cooling process is gradual enough to prevent the formation of any residual stresses in the component.

Inadequate venting can also cause the part to warp, so it is important to consider increasing the number or size of vents or changing their location to address the problem.

Suggested Read

- What is Hardness in Plastics? An In-Depth Guide

- How is Plastic Made? A Simple and Detailed Explanation.

- Physical Properties of Plastic Materials | The Complete Guide

- 6 Best Plastic Molding Techniques | A Complete Analysis

Final Words

Thus, were my knowledge and insights on warpage in plastic parts. I have tried my best to include all the necessary information. There are other types of injection molding defects, as mentioned above.

However, warpage is one of the more stubborn defects that persists even after essential steps are taken to prevent it. However, if you follow the guide correctly, you should easily be able to avoid warpage and to increase the quality of your production.

Feel free to comment on your reviews in the comment box.

Quick Navigation

I commend your dedication in crafting such an outstanding piece.

Thanks

Great insights on warpage! It’s interesting to see how even minor changes in the manufacturing process can lead to significant issues down the line. I especially appreciated the tips on prevention—definitely going to implement some of those strategies in our production workflow. Thanks for the informative guide!

Thanks for the feedback

Hi, I found your guide as I am compiling a few pages myself to educate colleagues and business partners about shrinkage and warpage. This is a nice summary you wrote. Just two remarks: 1. try to separate cause and effect clearer. Not doing so might lead to additional confusion. EG: you write about cooling rate as if this was a material property, while it is not. Cooling rate is a function of temperature gradient and then a combination of thermal conductivity, heat capacity, heat transfer coefficients etc. I know this is more granular than you might want to go, but still cooling rate is not a material property. 2. For illustration purposes it might be helpful to introduce pvT diagrams. These showcase that plastic melts are also compressible and also you can draw the injection molding process in the diagram that helps to explain directly the main processing parameters and hoe tool design and gate location are main drivers already.

I’ll take that into consideration.

Great post! I never realized how much factors like cooling rates and mold design could affect warpage in plastics. This guide really helped clarify some of my misconceptions. Looking forward to using these insights in my next project!

Thanks a bunch