Hey there, awesome folks! I trust you’re all thriving and buzzing with energy. Get ready because I’m about to unveil a captivating guide on the modulus of elasticity units or young modulus units. that will surely pique your interest and keep you hooked! Let’s dive in!

What is the Modulus of Elasticity Units

Get ready for a mind-bending journey into the world of elasticity! The modulus of elasticity, also known as the Young modulus or elastic modulus, is the ratio of stress applied to a material and the resulting deformation.

In simpler terms, it measures a material’s resistance to being temporarily squished or stretched.

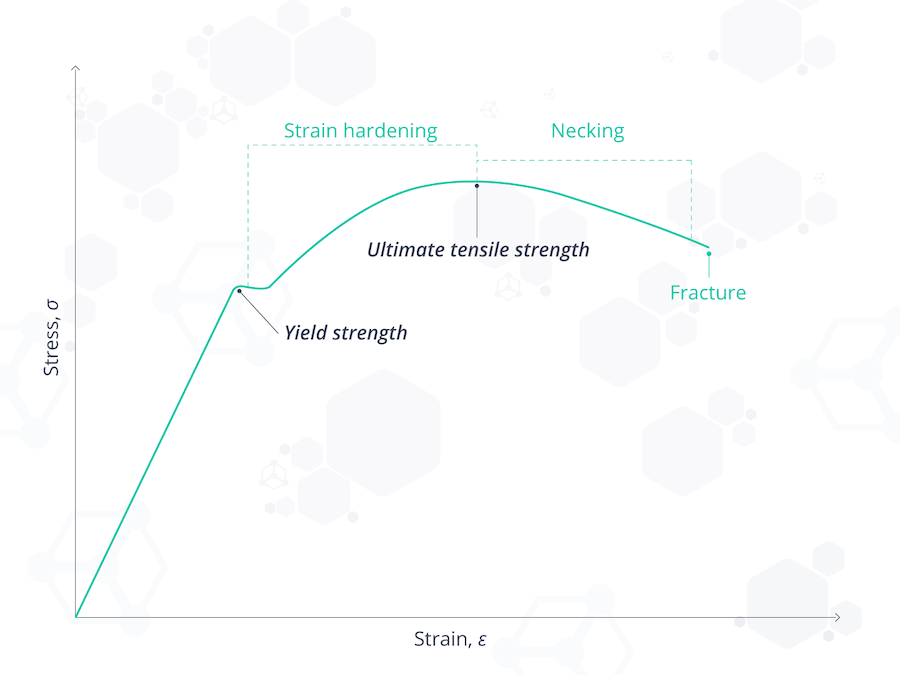

Picture this: an object stretches under tension, capturing its behavior through a stress-strain curve in the elastic deformation zone (Hooke’s Law, anyone?). The degree of stretch depends on the material and the object’s dimensions, like thickness, width, and length.

Here’s the twist: less stretchy materials have a higher elasticity modulus than their springier counterparts. Stress, defined as force per unit area, is measured in Nm-2 or Pa.

The Young modulus, often symbolized by the Greek letter lambda (λ), is calculated by dividing stress by strain.

So buckle up and embrace the power of elasticity!

λ= Stress/Strain

- Stress is the force that causes the deformation divided by the affected area.

- Strain is the displacement of the particle of the substance relative to a specific strength.

Image Credit - Matmatch.com

σ (stress) = F/A

If I try to simplify the equation and tell the meaning of each character, then σ is stress (in Newtons per square meter), F is force, and A is the cross-sectional area of the specimen.

On the other hand, strain is defined as extension per unit length, and strain has no units as it’s a ratio of units.

ε (strain) = ΔL/L0; ΔL = L-L0

In the above equation, the Lo represents the original length of the bar being stretched, and L represents its length which has been stretched. ΔL is the difference between these two lengths.

E = stress/strain = σ/ ε

Utilizing the tensile stress and tensile strain measurements, the material’s stiffness is differentiated by the modulus of elasticity, which is consent and doesn’t change for a given material. The formula representing the modulus of elasticity is:

E = stress/strain = σ/ ε

Types of Modulus of Elasticity Units

The two main types of elastic modulus coming under young’s modulus unit are:

- Shear modulus

- Bulk modulus

Shear Modulus

The shear modulus of a material determines its stiffness. It is useful when a force parallel to a given axis is combined with an opposing force, such as friction. Simply put, it’s the likelihood of a material changing from a rectangular shape to a parallelogram. Shear modulus can be defined as the ratio of shear stress to shear strain and is denoted by the symbols G, S, or µ.

The shear modulus is commonly used in calculations involving two materials in contact and subject to opposite forces. An excellent example of a phenomenon is rubbing together.

Bulk Modulus

The bulk modulus is a thermodynamic property that measures a material’s resistance to compression. In simple terms, it means the likelihood of the volume of a substance changing without changing its original shape. The ratio of pressure increase relative to volume decrease is what bulk modulus is about. Denoted by the symbols K or B, the bulk modulus is generally used for observing the properties of liquids under compression.

Interesting Read – What is the Density of Plastics? | The Complete Guide

Applications of Elasticity Modulus Units

Elastic modulus is essential in determining a material’s mechanical properties. The engineering and medical industry utilizes the elastic modulus the most.

- Essential to select various materials considering how they will be affected under different types of forces and stresses.

- Helping the designing process.

- Determining batch quality and reducing material costs require consistency in manufacturing.

How to Calculate Modulus of Elasticity

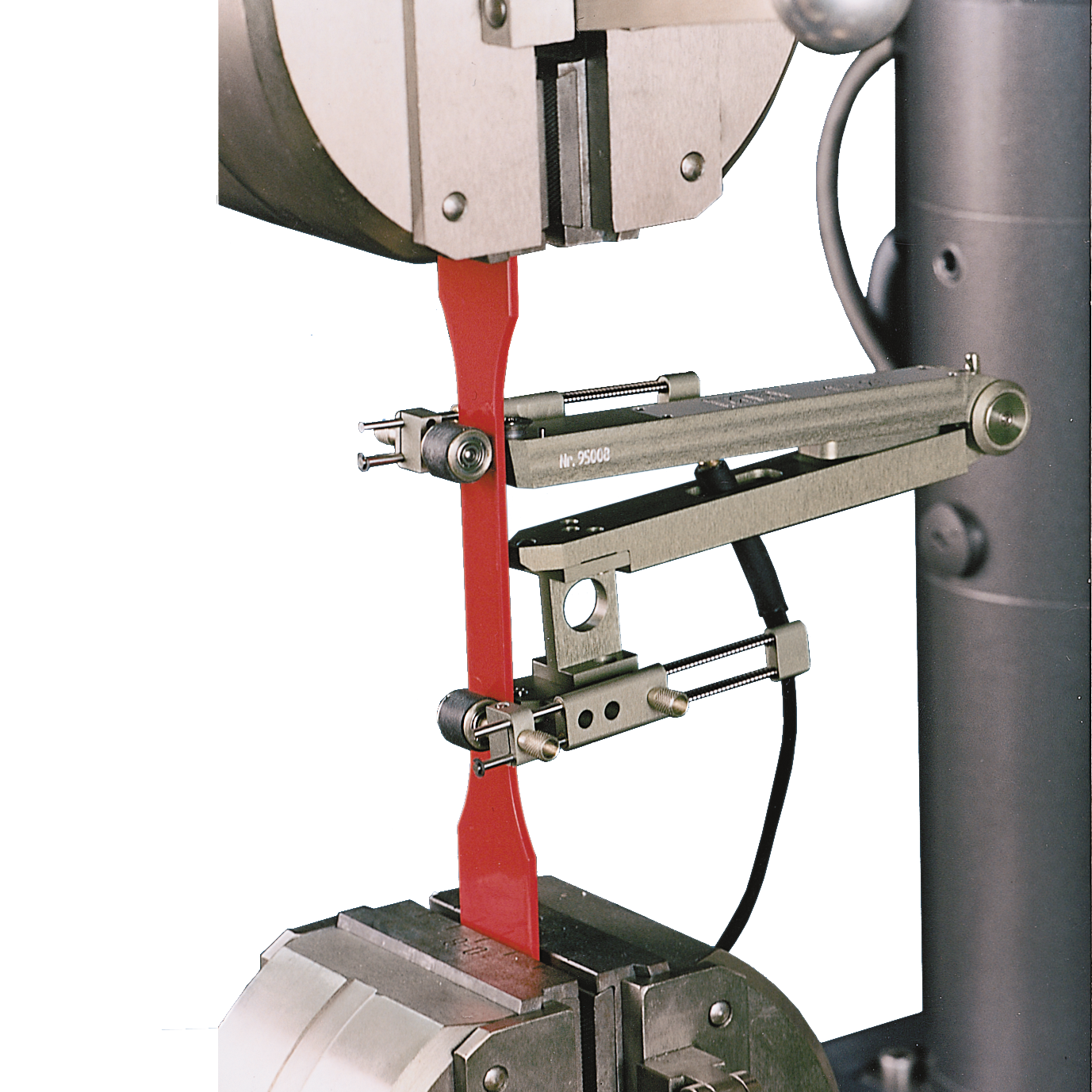

Generally, “tensile test methods” are utilized to determine the modulus of materials. These methods include the bending test or natural frequency vibration test, and tension test. Bending and tension testing methods follow Hooke’s law and are static methods. Natural frequency determines an accurate elastic modulus as the test utilizes vibrations.

The static methods are performed by applying quantifiable parallel or perpendicular forces and measuring and calculating the change in length or extent of deformation. Extensometers or mechanical strain gauges are the most preferred devices to operate as they’re good at measuring small lengths.

The common standards used for determining are:

- ASTM D638 – Test Method for Tensile Properties of Plastics

- ISO 527-1:2012 – Determination of tensile properties.

Engaging Read – What is the Glass Transition Temperature of Plastics?

ASTM D638 and ISO 527 Test Methods

An Extensometer

ASTM D638 and ISO 527 test methods determine tensile properties for plastic materials and composites under specific conditions in standard dumbbell-shaped test samples. The specified conditions are temperature, humidity, pretreatment, testing machine speed, etc.

The following results can be obtained for the tensile test results:

- Tensile strength

- Tensile modulus/ Young’s modulus

- Strain

- Elongation and percent elongation at yield

- Elongation and percent elongation at break

Regarding ASTM D638 test methods, the test speed depends on the specific material. However, for ISO 527 test, the speed is generally 5 or 50mm/min for measuring strength and elongation and 1mm/min for measuring modulus.

Factors Affecting Modulus of Elasticity

The modulus of elasticity is related to the atom’s binding energies. The young’s modulus and bending forces are generally higher for high melting point materials. The modulus of elasticity does depend on the positioning of a single crystal material.

The higher temperature in the materials results in a big jump in the atomic vibrations, decreasing the necessary energy to separate the toms further. That reduces the stress needed to produce a certain amount of strain.

Certain things can marginally or heavily weaken or strengthen a material with its presence, such as alloying atoms, impurity atoms, secondary phase particles, non-metallic inclusions, dislocations (mismatches in the lattice structure), and defects (cracks).

- Anything that hampers the motion of dislocations through the lattice will likely increase the modulus and yield strength.

- Increased temperature will aid the dislocation movement or create cracks or inclusions that will decrease strength by triggering the early onset of failure.

Interestingly, plastics’ modulus of elasticity falls way below that of metals, ceramics, or even glass. Below I have shared a table with young’s modulus units of mainstream plastic materials:

Tensile Modulus or Elastic Modulus Units of Mainstream Plastics

[su_table responsive=”yes”]

| Plastic Name | Minimum Value (Gpa) | Maximum Value (Gpa) |

| ABS – Acrylonitrile Butadiene Styrene | 1.79 | 3.2 |

| ABS Flame Retardant | 2 | 3 |

| ABS High Heat | 1.5 | 3 |

| ABS High Impact | 1 | 2.5 |

| ABS/PC Blend – Acrylonitrile Butadiene Styrene/Polycarbonate Blend | 2.1 | 2.3 |

| ABS/PC Blend 20% Glass Fiber | 6 | 6 |

| ABS/PC Flame Retardant | 2.6 | 3 |

| Amorphous TPI Blend, Ultra-high heat, Chemical Resistant (High Flow) | 3.5 | 3.5 |

| Amorphous TPI, High Heat, High Flow, Lead-Free Solderable, 30% GF | 10.53 | 10.52 |

| Amorphous TPI, High Heat, High Flow, Transparent, Lead-Free Solderable (High Flow) | 3.1 | 3.1 |

| Amorphous TPI, High Heat, High Flow, Transparent, Lead-Free Solderable (Standard Flow) | 3.16 | 3.16 |

| Amorphous TPI, Highest Heat, Chemical Resistant, 260°C UL RTI | 3.9 | 3.9 |

| Amorphous TPI, Moderate Heat, Transparent | 3.12 | 3.12 |

| Amorphous TPI, Moderate Heat, Transparent (Food Contact Approved) | 3.11 | 3.1 |

| Amorphous TPI, Moderate Heat, Transparent (Mold Release grade) | 3.12 | 3.12 |

| Amorphous TPI, Moderate Heat, Transparent (Powder form) | 3.11 | 3.11 |

| ASA – Acrylonitrile Styrene Acrylate | 2 | 2.6 |

| ASA/PC Blend – Acrylonitrile Styrene Acrylate/Polycarbonate Blend | 2 | 2.6 |

| ASA/PC Flame Retardant | 2.5 | 2.5 |

| ASA/PVC Blend – Acrylonitrile Styrene Acrylate/Polyvinyl Chloride Blend | 2 | 2.2 |

| CA – Cellulose Acetate | 0.6 | 2.8 |

| CAB – Cellulose Acetate Butyrate | 0.4 | 1.7 |

| Cellulose Diacetate-Pearlescent Films | 2 | 2.5 |

| Cellulose Diacetate-Gloss Film | 2 | 2.5 |

| Cellulose Diacetate-Integuard Films | 2.6 | 2.9 |

| Cellulose Diacetate-Matt Film | 2 | 2.9 |

| Cellulose Diacetate-Window Patch Film (Food Grade) | 2 | 2.5 |

| Cellulose Diacetate-Clareflect metalized film | 2.1 | 2.6 |

| Cellulose Diacetate-Colored Films | 2 | 2.6 |

| Cellulose Diacetate-Flame retardant Film | 2 | 2.5 |

| Cellulose Diacetate-High Slip Film | 2.3 | 2.8 |

| Cellulose Diacetate-Semitone Films | 2 | 2.5 |

| CP – Cellulose Proprionate | 0.45 | 1.4 |

| COC – Cyclic Olefin Copolymer | 2.6 | 3.2 |

| CPVC – Chlorinated Polyvinyl Chloride | 2.5 | 3.2 |

| ECTFE | 1.7 | 1.7 |

| ETFE – Ethylene Tetrafluoroethylene | 0.8 | 0.8 |

| EVA – Ethylene Vinyl Acetate | 0.01 | 0.2 |

| EVOH – Ethylene Vinyl Alcohol | 1.9 | 3.5 |

| FEP – Fluorinated Ethylene Propylene | 0.3 | 0.7 |

| HDPE – High Density Polyethylene | 0.5 | 1.1 |

| HIPS – High Impact Polystyrene | 1.5 | 3 |

| HIPS Flame Retardant V0 | 2 | 2.5 |

| Ionomer (Ethylene-Methyl Acrylate Copolymer) | 0.9 | 0.4 |

| LCP – Liquid Crystal Polymer | 10 | 19 |

| LCP Carbon Fiber-reinforced | 31 | 37 |

| LCP Glass Fiber-reinforced | 13 | 24 |

| LCP Mineral-filled | 12 | 22 |

| LDPE – Low-Density Polyethylene | 0.13 | 0.3 |

| LLDPE – Linear Low-Density Polyethylene | 0.266 | 0.525 |

| MABS – Transparent Acrylonitrile Butadiene Styrene | 1.9 | 2 |

| PA 11 – (Polyamide 11) 30% Glass fiber reinforced | 3.8 | 5.2 |

| PA 46 – Polyamide 46 | 1 | 3.3 |

| PA 46, 30% Glass Fiber | 7.8 | 8.2 |

| PA 6 – Polyamide 6 | 0.8 | 2 |

| PA 6-10 – Polyamide 6-10 | 1 | 2 |

| PA 66 – Polyamide 6-6 | 1 | 3.5 |

| PA 66, 30% Glass Fiber | 5 | 8 |

| PA 66, 30% Mineral filled | 1.4 | 5.5 |

| PA 66, Impact Modified, 15-30% Glass Fiber | 2 | 11 |

| PA 66, Impact Modified | 0.8 | 1.2 |

| Polyamide semi-aromatic | 2.07 | 2.23 |

| PAI – Polyamide-Imide | 4 | 5 |

| PAI, 30% Glass Fiber | 11 | 15 |

| PAI, Low Friction | 5 | 7 |

| PAN – Polyacrylonitrile | 3.1 | 3.7 |

| PAR – Polyarylate | 2 | 2.3 |

| PARA (Polyarylamide), 30-60% glass fiber | 11.5 | 24 |

| PBT – Polybutylene Terephthalate | 2 | 3 |

| PBT, 30% Glass Fiber | 9 | 11.5 |

| PC (Polycarbonate) 20-40% Glass Fiber | 6 | 10 |

| PC (Polycarbonate) 20-40% Glass Fiber Flame Retardant | 7 | 8 |

| PC – Polycarbonate, high heat | 2.2 | 2.5 |

| PC/PBT Blend – Polycarbonate/Polybutylene Terephthalate Blend | 1.8 | 2.3 |

| PC/PBT blend, Glass Filled | 4.5 | 5.1 |

| PCL – Polycaprolactone | 0.38 | 0.43 |

| PCTFE – Polymonochlorotrifluoroethylene | 1.2 | 1.5 |

| PE – Polyethylene 30% Glass Fiber | 4.9 | 6.3 |

| PE/TPS Blend – Polyethylene/Thermoplastic Starch | 0.18 | 0.3 |

| PEEK – Polyetheretherketone | 3.5 | 3.9 |

| PEEK 30% Carbon Fiber-reinforced | 13 | 22.3 |

| PEEK 30% Glass Fiber-reinforced | 9 | 11.4 |

| PEI – Polyetherimide | 3 | 3 |

| PEI, 30% Glass Fiber-reinforced | 9 | 9 |

| PEI, Mineral Filled | 5 | 7 |

| PEKK (Polyetherketoneketone), Low Crystallinity Grade | 3.5 | 3.6 |

| PESU – Polyethersulfone | 2.3 | 2.8 |

| PESU 10-30% glass fiber | 3.5 | 8.5 |

| PET – Polyethylene Terephthalate | 2.8 | 3.5 |

| PET, 30% Glass Fiber-reinforced | 9 | 12 |

| PET, 30/35% Glass Fiber-reinforced, Impact Modified | 7 | 9 |

| PETG – Polyethylene Terephthalate Glycol | 1.9 | 2 |

| PFA – Perfluoroalkoxy | 0.7 | 0.8 |

| PGA – Polyglycolides | 6.5 | 6.9 |

| PHB – Polyhydroxybutyrate | 3.1 | 3.3 |

| PI – Polyimide | 1.3 | 4 |

| PLA – Polylactide | 3.4 | 3.6 |

| PLA, High Heat Films | 3.3 | 3.5 |

| PLA, Injection molding | 3.5 | 3.6 |

| PMMA – Polymethylmethacrylate/Acrylic | 2.5 | 3.5 |

| PMMA (Acrylic) High Heat | 2.5 | 4.3 |

| PMMA (Acrylic) Impact Modified | 1.5 | 3.5 |

| PMP – Polymethylpentene | 0.5 | 1.6 |

| PMP 30% Glass Fiber-reinforced | 5 | 6 |

| PMP Mineral Filled | 1.7 | 2 |

| POM – Polyoxymethylene (Acetal) | 2.8 | 3.7 |

| POM (Acetal) Impact Modified | 1.5 | 2.4 |

| POM (Acetal) Low Friction | 1.8 | 3 |

| POM (Acetal) Mineral Filled | 4 | 5.5 |

| PP – Polypropylene 10-20% Glass Fiber | 2.8 | 4 |

| PP, 10-40% Mineral Filled | 1 | 3.5 |

| PP, 10-40% Talc Filled | 1.5 | 3.5 |

| PP, 30-40% Glass Fiber-reinforced | 4 | 10 |

| PP (Polypropylene) Copolymer | 1 | 1.2 |

| PP (Polypropylene) Homopolymer | 1.1 | 1.6 |

| PP Homopolymer, Long Glass Fiber, 30% Filler by Weight | 7 | 7 |

| PP Homopolymer, Long Glass Fiber, 40% Filler by Weight | 9 | 9 |

| PP Homopolymer, Long Glass Fiber, 50% Filler by Weight | 12 | 13.5 |

| PP, Impact Modified | 0.4 | 1 |

| PPA – Polyphthalamide | 3.7 | 3.7 |

| PPA, 33% Glass Fiber-reinforced – High Flow | 13 | 13.2 |

| PPA, 45% Glass Fiber-reinforced | 17.1 | 17.3 |

| PPE – Polyphenylene Ether | 2.1 | 2.8 |

| PPE, 30% Glass Fiber-reinforced | 7 | 9 |

| PPE, Flame Retardant | 2.4 | 2.5 |

| PPE, Impact Modified | 2.1 | 2.8 |

| PPE, Mineral Filled | 2.9 | 3.5 |

| PPS – Polyphenylene Sulfide | 3.3 | 4 |

| PPS, 20-30% Glass Fiber-reinforced | 6 | 11 |

| PPS, 40% Glass Fiber-reinforced | 8 | 14 |

| PPS, Conductive | 13 | 19 |

| PPS, Glass fiber & Mineral-filled | 10 | 17 |

| PPSU – Polyphenylene Sulfone | 2.34 | 2.34 |

| PS (Polystyrene) 30% glass fiber | 10 | 10 |

| PS (Polystyrene) Crystal | 2.5 | 3.5 |

| PS, High Heat | 3 | 3.5 |

| PSU – Polysulfone | 2.5 | 2.7 |

| PSU, 30% Glass fiber-reinforced | 7.7 | 10 |

| PSU Mineral Filled | 3.8 | 4.5 |

| PTFE – Polytetrafluoroethylene | 0.4 | 0.8 |

| PTFE, 25% Glass Fiber-reinforced | 1.4 | 1.7 |

| PVC (Polyvinyl Chloride), 20% Glass Fiber-reinforced | 4.6 | 7 |

| PVC, Plasticized | 0.001 | 1.8 |

| PVC, Plasticized Filled | 0.001 | 1 |

| PVC Rigid | 2.4 | 4 |

| PVDC – Polyvinylidene Chloride | 0.35 | 0.5 |

| PVDF – Polyvinylidene Fluoride | 1.5 | 2 |

| SAN – Styrene Acrylonitrile | 2.8 | 4 |

| SAN, 20% Glass Fiber-reinforced | 8 | 11 |

| SMA – Styrene Maleic Anhydride | 2.4 | 3 |

| SMA, 20% Glass Fiber-reinforced | 5 | 6 |

| SMA, Flame Retardant V0 | 1.8 | 2 |

| SMMA – Styrene Methyl Methacrylate | 2.1 | 3.4 |

| SRP – Self-reinforced Polyphenylene | 5.9 | 8.3 |

| TPI-PEEK Blend, Ultra-high heat, Chemical Resistant, High Flow, 240C UL RTI | 4.2 | 4.2 |

| TPS, Injection General Purpose | 0.8 | 3 |

| TPS, Injection Water Resistant | 0.63 | 0.72 |

| UHMWPE – Ultra High Molecular Weight Polyethylene | 0.3 | 0.6 |

| XLPE – Crosslinked Polyethylene | 0.35 | 3.5 |

[/su_table]

Fascinating Read – What is Processing and Drying Temperatures of Plastics

FAQs

Is a higher Young’s modulus better?

A higher Young’s modulus means more stiffness. Simply put, the elastic strain resulting from applying given stress is smaller. The modulus is an essential metric for determining elastic deflections. Plastics have lower modulus elasticity compared to metals, glass, and ceramics.

What are the factors on which the modulus of elasticity depends?

The modulus of elasticity is dependent mainly on two factors – 1. nature of the material and 2. type of stress used in producing the strain.

What is the stiffest plastic?

A plastic material named Primospire has the stiffest to date. It has a flexural modulus of 1.2 million psi and a tensile strength of 30,000 psi.

What does modulus of elasticity equal?

Modulus of elasticity is equal to the longitudinal stress divided by the strain. However, the deformation is measured on the same axis.

What is the relation between elasticity and modulus of resilience?

Modulus of elasticity and modulus are much more similar than most people know. The critical difference between the both is that the stress is applied slowly in the former, and the load is applied rapidly in the latter.

Suggested Read –

- Plastic Abbreviations and Their Salient Features | The Ultimate Guide

- What is Warpage? | Causes of Warpage | Warpage Variations

- 6 Best Plastic Molding Techniques | A Complete Analysis

- What is Rotational Molding | Rotational Molding Process | Advantages & Disadvantages | Best Material for Rotational Molding

- What is Compressive Strength of Plastics | The Complete Guide

- Thermal Properties of Plastics | The Ultimate Guide

- Mold Temperature in Plastics | A Complete Analysis

- Physical Properties of Plastic Materials | The Complete Guide

The Conclusion

That was all I had to say about the modulus of elasticity and related information. The applications of modulus of elasticity are immense in the engineering industry providing experts with accurate data on plastic stiffness, which helps them make robust products used by consumers like ourselves.

Kindly share your thoughts and reviews in the comment section.

Have a fantastic day.

Quick Navigation

Very well explained. Keep it up.

Thanks for the appreciation.